China spring cone crusher for sale, cone crusher supplier

2024-07-09

staurk

What is a spring cone crusher

The spring cone crusher is an early type of cone crusher, which was developed based on the digestion and absorption of various types of cone crushers from various countries in the 1980s.

The spring safety system is an overload protection device that can allow metal foreign objects to pass through the crushing chamber without harming the machine.

It adopts two sealing forms, dry oil or water, to isolate the stone powder from the lubricating oil and ensure reliable operation.

The form of the crushing chamber is determined by the purpose of the ore, and the standard type is suitable for medium crushing; Medium size suitable for fine crushing; The short head type is suitable for fine crushing.

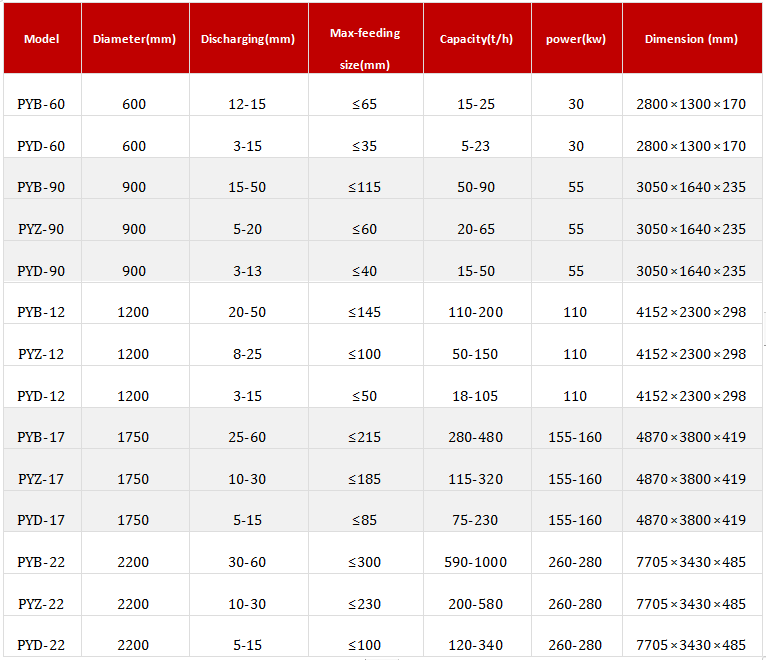

Spring cone crusher parameter

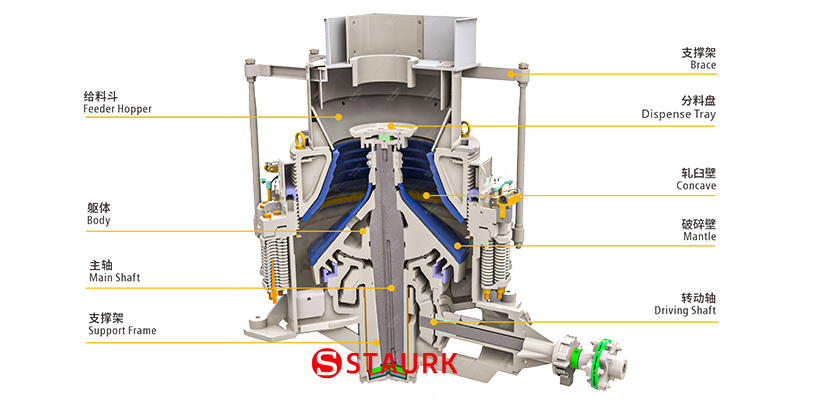

What is the Spring cone crusher structure

Spring cone crusher including feeder hopper, brace,dispense tray,concave,mantle,driving shaft,main shaft,body and support frame etc.

Spring cone crusher Application:

Coarse, medium, and fine materials with compressive strength not exceeding 350MPa, such as river pebbles, granite, basalt, iron ore, shale, limestone, coal gangue, quartz, diabase, marble, copper ore, pebbles, etc.

Widely used in industries such as mineral processing, coal, building materials, chemical industry, refractory materials, metallurgy, cement, glass, ceramics, power, etc

What is the Spring cone crusher features

1. The moving cone rotates continuously, and the material alternates and continues along the working surface during the crushing and unloading processes, resulting in high productivity.

2. The material is sandwiched between two cones and is subjected to compression, bending, and shearing, making it easier to break and consuming less power.

3. The product has a relatively uniform material density and a cubic shape, and the wear on the working surface of the moving cone is also relatively uniform.

4. Introduction to the structure: The cone crusher mainly consists of a frame, horizontal axis, moving cone, balance wheel, eccentric sleeve, upper crushing wall (fixed cone), lower crushing wall (moving cone), hydraulic coupling, lubrication system, hydraulic system, control system, etc.

Operation tips

1. Before starting the main engine, first turn on the thin oil station and confirm that the system lubrication is normal before starting the main engine. Wait for the spring cone crusher to run normally before starting the feeder. Before stopping the spring cone crusher, stop feeding and wait for all the ore in the crushing chamber to be discharged before stopping. Finally, turn off the oil pump in the thin oil station.

2. Before starting the oil pump in the thin oil station, open the corresponding oil-water valve and pressure gauge switch, adjust the pressure regulator to ensure that the oil pressure is within the range of 0.04-0.1Mpa, and the oil temperature should be within the range of 30-40 ℃. If the oil temperature is too low, first turn on the resistance heater to heat the oil.

3. The functions of each electrical switch are detailed in the instruction manual of the electrical control cabinet, and should be placed in an appropriate

Tips before operation

(1) No load test

1. Before starting the spring cone crusher, it is necessary to check the tightness of the main connections and rotate the eccentric sleeve by hand for at least 2-3 turns. It should be flexible and free of jamming before starting.

2. Before starting, start the oil pump until each lubrication point receives lubricating oil before starting the spring cone crusher.

3. The continuous operation of the idle test shall not be less than 2 hours.

4. The air freight test should meet the following requirements:

(1) The rotational speed of the broken cone around its centerline shall not exceed 15r/min

(2) Bevel gears must not have periodic noise.

(3) The oil pressure should be within the range of 0.08-0.15Mpa.

(4) The return oil temperature should not exceed 50 ° C.

(5) After the experiment, the friction parts of the spring cone crusher should not have copper sticking, burns, or wear during disassembly.

5. If there is any adverse phenomenon in the number of broken cone rotations, the vehicle should be stopped immediately for inspection and correction. Colleagues check the amount of oil provided and then retest.

6. If there is periodic noise from the bevel gear, the correctness of the bevel gear must be checked, and the clearance of the bevel gear must be checked.

(2) Load test

1. After passing the air freight test, the load test can be carried out.

2. The load test should be conducted continuously for 24-48 hours.

3. The load test begins by adding a small amount of ore and gradually increasing to full load.

4. The load test should meet the following requirements.