Four roller crusher roll manufacturer China

4 roller crusher:

The four-roll crusher is actually a new type of equipment that combines a pair of roller crusher (double smooth roller crusher) and a double tooth roller crusher. It can be combined with two smooth rollers or one smooth roller and one toothed roller. Compared with the double-toothed roller crusher and the double-toothed roller crusher, the technical content is more advanced, the structure is more compact, and the crushing ratio is larger.

Four roll crusher, also known as 4PG four-roll crusher, four-roller, etc., is a kind of metallurgical mining equipment supporting medium, fine and ultra-fine crushed products. By adjusting the gap between the upper and lower rollers, the crushed materials with the required particle size can be obtained.

Types of Four Roll Crusher:

A. Four-grinding and two-crushing machine

Feeding size : ≤90mm

Discharing size : 60 mesh (0.42mm) - 5mm

The four-roller and two-crusher model is a general-purpose four-roller crusher.

The four grinding surfaces are divided into surfacing grinding surfaces, and the combination is selected according to the particle size required by the user.

B. Four grinding and three crushing machine

Feeding size : ≤90mm

Discharing size : 100 mesh (0.15mm) - 5mm

The four grinding surfaces are divided into surfacing roller surfaces or flat roller surfaces, and the combination is selected according to the particle size required by the user.

Tooth of four roller crusher

Tooth of four roller crusher

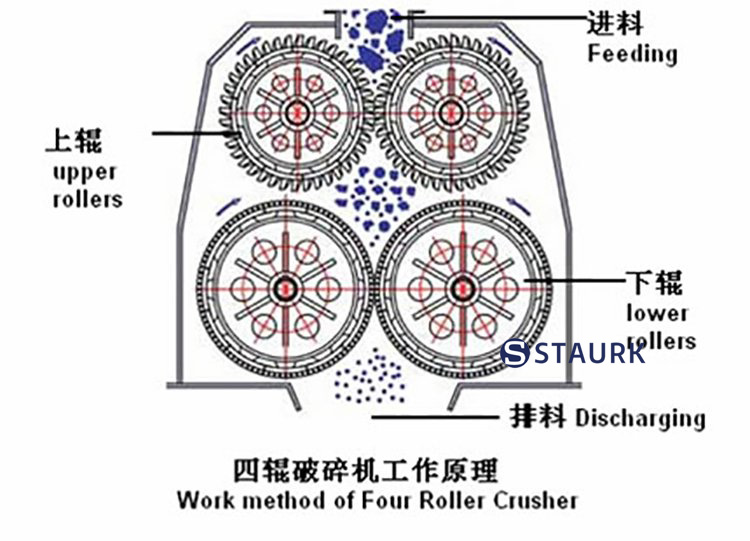

Structure and working principle of four roller crusher

The four-roll crusher uses four high-strength wear-resistant alloy rollers to crush materials,with high extrusion force and shear force generated by relative rotation.

1.Coarse crushing: Under the action of the extrusion force, the material is squeezed and crushed for the first time (coarse crushing), and then enters the relatively rotating middle two rolls,

2.fine crushing: and the extrusion force of the middle two rolls is used for secondary extrusion and crushing (fine crushing). ,

3.ultrafine crushing: and finally enter the next two rolls, and then use the next two rolls for the third extrusion, shearing and crushing (ultrafine crushing), and then crushed into the required particle size and discharged from the discharge port.

Application:

widely used for crushing river pebble, calcite, quartz stone, marble, cobblestone, bentonite, iron ore, limestone, quicklime, quartz sand, bluestone, mountain stone, water slag, bauxite, kaolin, weathered sand, diabase , granite, basalt and other materials crushing

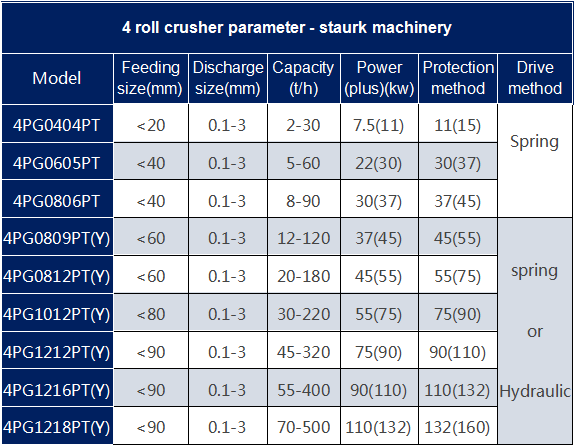

Parameter of the Four roller crusher

Advantages of Four Roll Crusher:

1. The discharge granularity is adjustable.

2. Less noise, less vibration and less dust.

3. The energy saving and environmental protection crushing ratio is large.

4. Small footprint and easy maintenance.

5. There is no requirement for the moisture content of the crushed material, and it is not sticky or blocked.

6. The uniform distribution device and the fine sieve powder device are integrated into one design.

7. Hydraulic or spring automatic retreat device and debris removal device.

Other features:

1.High yield

Four-roll crusher adopts single-machine secondary crushing, that is, coarse crushing and fine crushing, which are realized in the machine cavity at the same time. It is one of the new alternative products of traditional crushing equipment.

2. Energy saving

The motive power motor of the four-roll crusher is 60% of the power motor of other crushers. The energy consumption alone can save more than 300,000 yuan a year compared with similar products.

3. Longer life

The working amplitude of the four-roll crusher is less than or equal to 0.03mm, which is one of the equipment with smaller amplitude in the current crushing equipment, and the service life of the whole machine is more than 30 years.

4. Low noise

The working noise of the four-roll crusher is ≤85dB at 1 meter and ≤60dB at 10 meters, and its noise conforms to the national new industrial product noise control standard.

Test run commission :

1. No-load test run

The no-load test runs for four hours, and if there is no problem, the load test is carried out.

(2) Preparations before the test run

①Comprehensive check whether the machine installation and electrical control circuit are correct;

② Check whether the connection of each part is correct and whether the fastening screws are firm;

③The bearing position and friction surface are filled with lubricating oil. The lubricating oil of the reducer should be kept between the oil mark marks, and it should not be too much or too little;

④ Before driving, turn the coupling by hand to check whether there is any lag phenomenon;

⑤ Check whether the hydraulic protection adjustment system has sufficient pressure, and whether the pressure display of each pressure gauge is correct.

After inspection, the test drive can be carried out after confirming that there is no problem with the machine parts.

(3) No-load test run

During the test run, observe and pay attention to the following matters

①The two motors of the crusher must be started at the same time;

②The rotation direction of the roller must be correct;

③The temperature rise of the bearing is not allowed to exceed 50℃, and the reducer and motor should have no abnormal noise.

After the test run, check whether the connecting bolts are loose, if any, remove them.

2. Load test

(1) The load test can be carried out only after the no-load test is qualified;

(2) In addition to paying attention to the above items during the load test, attention should be paid to gradually increase the material to the full load, and not to add enough at one time;

(3) The feeding material should be evenly distributed along the length of the roller;

(4) After the load test run for eight hours, if it is confirmed that there is no problem, it can be put into production and use.