Gold centrifuge knelson concentrator manufacturer China

Condition:New,for sale , from China manufacturer

Advantage:Upgrade 1000 times for low-grade raw mining in short time

Type:Automatic dischage, batch type, semi continous , continous

Capacity:0.2-120 Ton per hour per set

Feeding size:< 0 - 6 mm (0 - 2mm is better)

Used for: the recovery of gold, tin, cobalt , copper, Platinum, Palladium, tungsten, lead, manganese, iron, etc. specially for recovery of fine gold which is lost during the operation of hard rocks, to replace amalgamation, recovery gold from tailings.

Gold centrifuge knelson concentrator manufacturer China

Why choose centrifugal concentrator ?

Gold Centrifuge concentrator is a new trend gravity separation equipment, which combines the advantages of other gravity separation equipment.

It can:Upgrade 1000 times for low-grade raw mining in short time

Gold centrifugal concentrator video

Introduction

Gold centrifugal concentrator is an important gravity beneficiation equipment . It is proved by experienced practices that this equipment is high efficient for recovery of alluvial gold , placer gold, rock gold, lode gold and monomeric gold in multi-metal ore.

It had earned high reputation for replacing mercury plate or any toxic chemical, removing the chemical harm to human body and conductive to environmental protecting.

The centrifugal machine gets many competitive advantages compared with other concentration machines which create high returns for the investors.

Application of centrifugal concentrator ?

Widly used for: the recovery of gold, tin, cobalt , copper, Platinum, Palladium, tungsten, lead, manganese, iron, etc. specially for recovery of fine gold which is lost during the operation of hard rocks, to replace gold amalgamator , recovery gold from tailings.

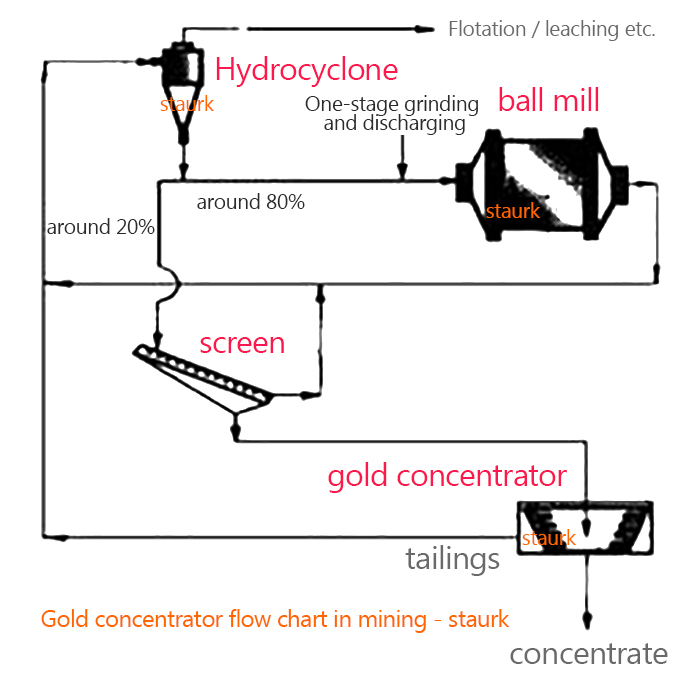

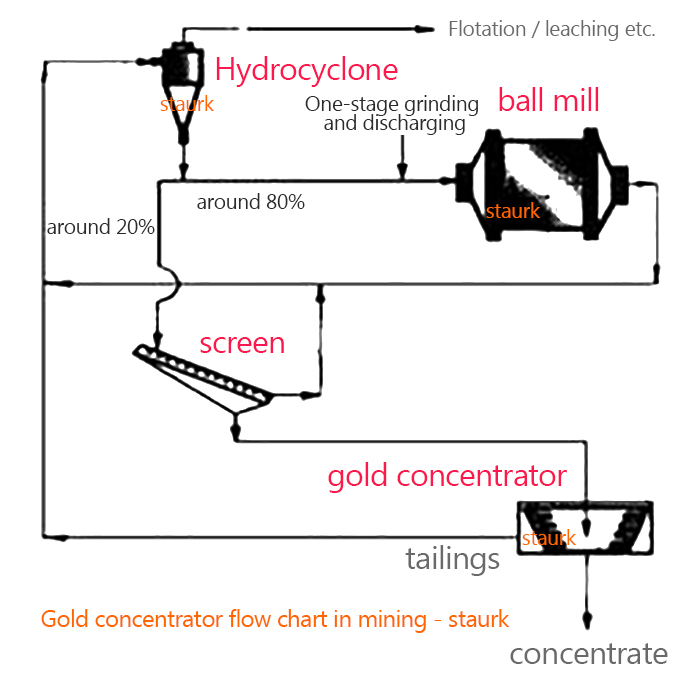

Gold Concentrator flow charts in mining , take as an reference:

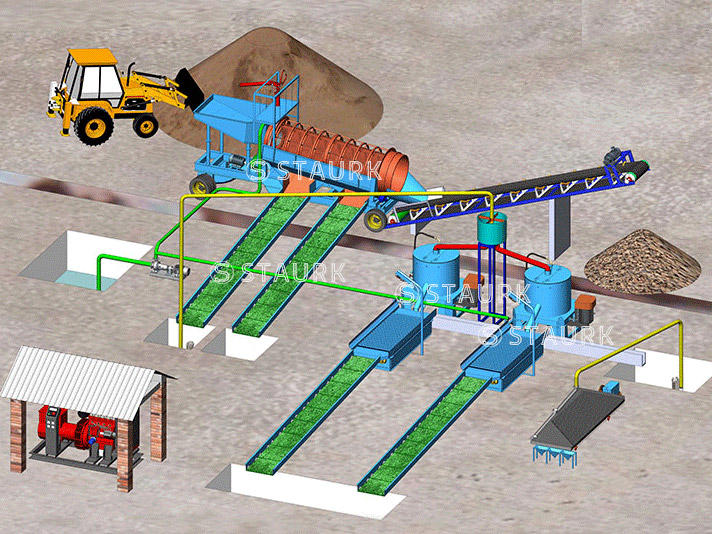

Gold Concentrator in alluvial placer mining plant

Gold concentrator in stone mining gravity plant

Models of centrifugal concentrator

Lab Gold concentrator for sale

Used in small capacity or laboratory.

STLB 20 Gold concentrator

Power: 0.75kw

STLB30 Gold concentrator

Power: 1.5kw

STLB30 Gold concentrator

Power: 1.5kw

STLB 60 Gold concentrator

Power: 5.5kw

STLB 60 Gold concentrator

Power: 5.5kw

STLB 80 Gold concentrator

Power: 11kw

STLB 80 Gold concentrator

Power: 11kw

STLB 100 Gold concentrator

Power: 18.5kw

STLB 100 Gold concentrator

Power: 18.5kw

STLB 120 Gold concentrator

STLB 120 Gold concentrator

Simple Gold centrifugal concentrator for sale

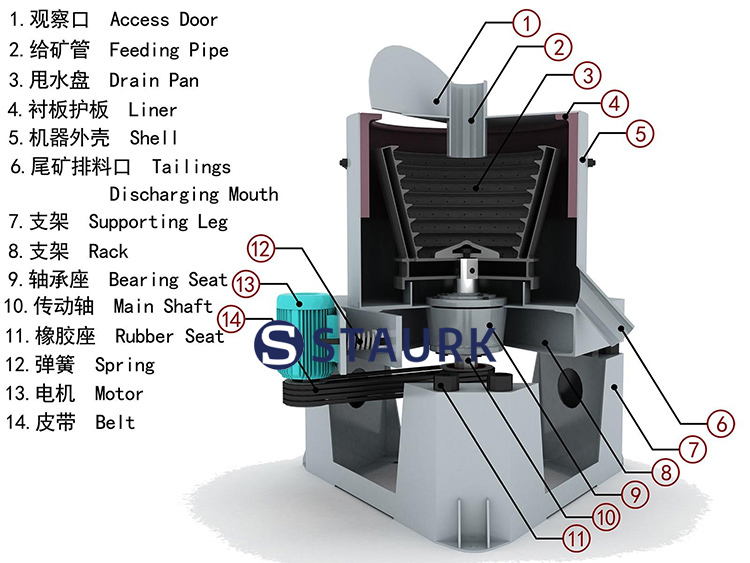

Structure:

Gold Centrifugal concentrator consist of access door,feeding pipe,drain pan,liner, shell,tailings,disharging mouth,support leg, rack, bear seat, main shaft,rubber seat, spring, motor and belt etc.

Parameter of the Centrifugal Knelson concentrator

|

Model |

STLB 20 |

STLB 30 |

STLB 40 |

STLB 60 |

STLB 80 |

STLB 100 |

STLB 120 |

|

Capacity (t/h) |

0.25-1 |

2-8 |

10-40 |

30-60 |

50-80 |

70-100 |

90-120 |

|

Feeding size (mm) |

0-3 |

0-4 |

0-6 |

0-6 |

0-6 |

0-6 |

0-6 |

|

Feeding Density (%) |

0-50 |

0-50 |

0-50 |

0-50 |

0-50 |

0-50 |

0-50 |

|

Water Required (t/h) |

1.5-2 |

4-6 |

10-15 |

17-25 |

20-30 |

40-60 |

70-80 |

|

Concentrate (Kg/time) |

2-3 |

10-20 |

30-40 |

50-60 |

60-70 |

70-80 |

110-120 |

|

Power (kw) |

0.75 |

1.5 |

5.5 |

7.5 |

11 |

18.5 |

22 |

|

cone speed (r/min) |

800 |

600 |

460 |

430 |

400 |

360 |

360 |

|

pressure water (Mpa) |

0.04 |

0.12 |

0.25 |

0.3 |

0.35 |

0.4 |

0.5 |

|

Dimension (m) |

0.8×0.8×0.8 |

1.2×1.2×1.3 |

2 ×1.7×1.8 |

2.1 ×1.7×2 |

2.3×1.8×2.2 |

2.5×2.0×2.4 |

2.7 ×2.2×2.6 |

|

Weight (kg) |

145 |

400 |

1300 |

1900 |

2000 |

2500 |

3000 |

Working principle

The equipment is driven by motor and driven by belt, which makes the inner sleeve rotate at high speed. The slurry is fed to the inner sleeve through the feeding pipe, and the slurry is strengthened by centrifugal force. Heavy minerals stay in the inner sleeve, and concentrate will be discharged from the discharge port after shutdown.Mainly has STLB or STL 20 30 60 80 100

Related article : How to operate, maintain, clean Gold Centrifugal Concentrator

Features

1.High recovery rate: Through our test, the recovery rate for placer gold can be 98% or more, for rock gold, the recovery rate could reach 97% when the feeding size is below 0.04mm.

2.High efficiency: STL60 gold panning concentrates machine has a capacity of 10-20TPH, and STL100 gold panning concentrates machine has a capacity of 50-80TPH. Only one machine could give you such a high

3.capacity and high recovery rate. It's the most efficient concentration equipment in our factory.

4.Easy to install: only a small leveled place required. It's a complete machine, before starting it, only need to connect the fluidization water and power.

5.Easy to adjust: there are only 2 factors that will affect the recovery result, they are water pressure and feeding size. By giving proper water pressure and feeding size, you could get the best recovery effect.

6.Easy to operate: after finishing the water pressure and feeding size adjust, what U have to do is to fetch the concentrates every 2-4 hours. (Depending on the grade of the mine)

7.No pollution: this machine only consumes water and electric power, and exhaust tailings and water. Low noise, no chemical agent involved.