China PE 150 250 400 600 stone jaw crusher for sale

Condition:New

Origin:Henan, China

Capacity:0.5-200 Ton/h

Max feed size:80-480 mm

Motor Power:2.2-75 kw

Used for:the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, metallurgy, and chemical industries.

China PE 150 250 400 600 stone jaw crusher for sale

Description:

Large stone jaw crusher working video

Stone jaw crusher test video

Jaw crusher is widely used in various industries, such as mining, road and railway construction, building construction,water conservation and chemical industry etc. It could crush kinds of minerals and rocks with compression strength less than 320MPa, such as quartz, granite, basalt, limestone, river stone, sandstone, shale, iron ore, copper ore, gold ore etc.

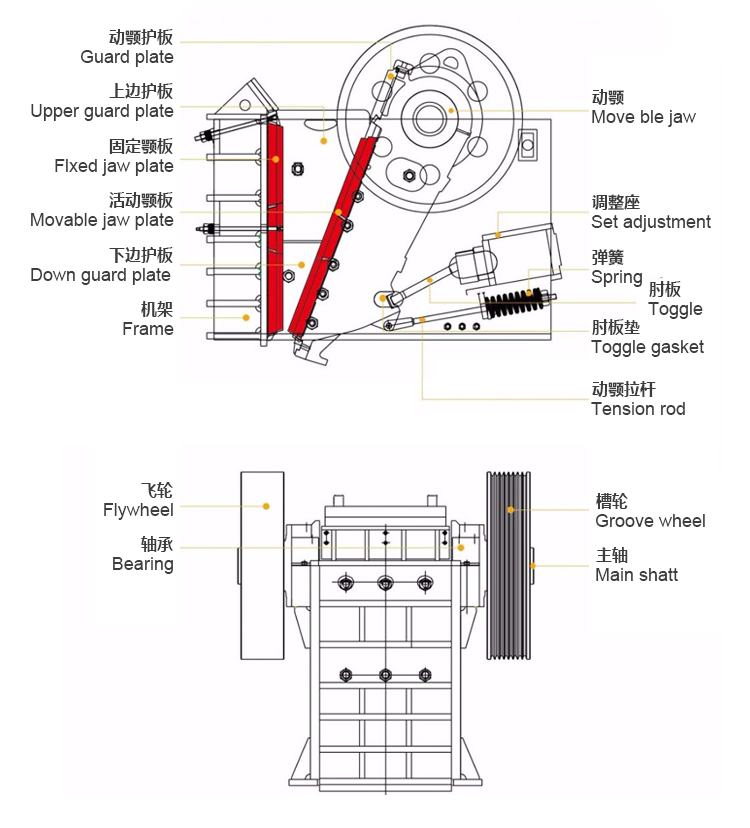

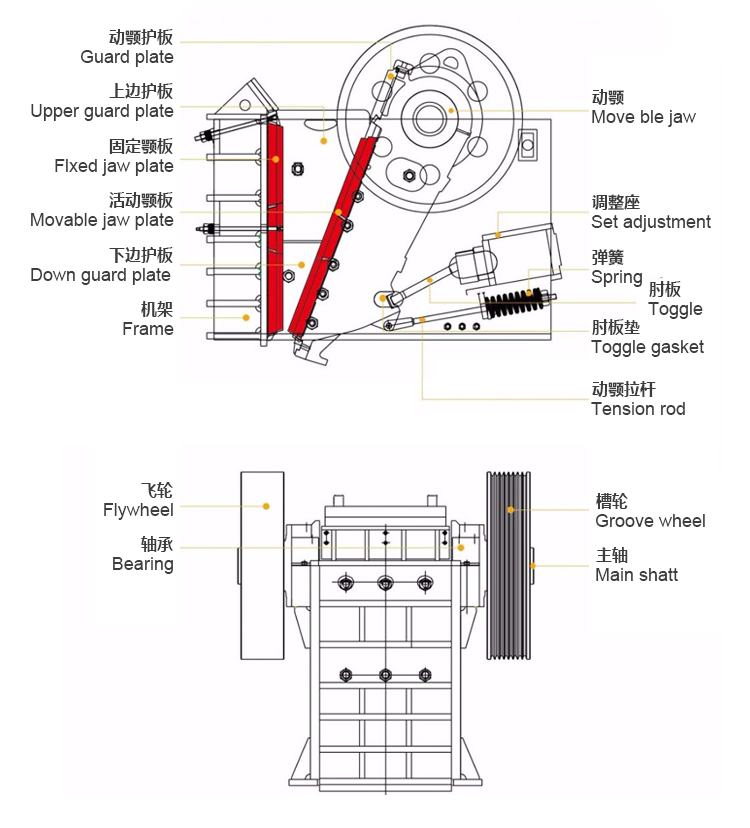

Jaw crusher Structure

Jaw crusher Structure

The electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or splitt when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turn back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulk-production comes true while electromotor rotates continuously and the movable jaw crushes and discharges the raw material periodically.

Related:

Jaw crusher for sale

Parameter of the Stone jaw crusher

|

Model |

Max-feeding size(mm) |

Discharging size(mm) |

Capacity(tph) |

Motor model |

Power(kw) |

Spindle speed(rpm) |

Dimension(L*W*H mm) |

Weight(t) |

|

PEF150×250 |

125 |

10~40 |

1~4 |

Y132S—4 |

5.5 |

300 |

875×745×935 |

0.6 |

|

PEF250×400 |

210 |

20~60 |

3~13 |

Y180L—6 |

15 |

300 |

1320×1210×1220 |

2.8 |

|

PEF400×600 |

350 |

40~110 |

10~34 |

Y250M—8 |

30 |

275 |

1700×1742×1530 |

6.7 |

|

PEF500×750 |

425 |

50~100 |

28~60 |

Y280M—6 |

55 |

275 |

1890×1916×1870 |

9.9 |

|

PEF600×900 |

500 |

75~200 |

56~192 |

JR117—8 |

80 |

250 |

2600×3700×2400 |

16.8 |

|

PEX150×500 |

120 |

10~40 |

3~15 |

Y160L—6 |

11 |

320 |

1170×1276×1082 |

2.5 |

|

PEX150×750 |

120 |

10~50 |

8~35 |

Y200L—6 |

18.5 |

300 |

1215×1521×1031 |

3.5 |

|

PEX250×750 |

210 |

15~50 |

13~45 |

Y225M—6 |

30 |

300 |

1400×1691×1412 |

5.8 |

|

PEX250×1000 |

210 |

15~50 |

15~50 |

Y225M—6 |

37 |

280 |

1530×1992×1380 |

6.4 |

|

PEX250×1200 |

210 |

15~50 |

20~60 |

JR115—8 |

37 |

330 |

1840×2192×1580 |

7.7 |

FAQ:

1. what is the output size of the jaw crusher?

2. what is the input size of the jaw crusher?

3. what is the capacity of the jaw crusher?

4. what is the powof the jaw crusher?

Answer:

these are normal qustions about jaw crusher

For example:

PE150x250 jaw crusher

input size: < 125 mm output size:10 - 40 mm

capacity:2 - 6 ton per hour power: 7.5 kw

PE200x350 jaw crusher

input size: < 160 mm output size:10 - 50 mm

capacity:6 - 10 ton per hour power: 7.5 kw

PE250x400 jaw crusher

input size: < 210 mm output size:20 - 60 mm

capacity:8 - 16 ton per hour power: 15 kw

you can check the parameter below.

We supply the different crushers:

1.The stationary crusher with electric motor.

2.The stationary crusher with diesel engine.

3.The mobile crusher with electric motor.

4.The mobile crusher with diesel engine.

5.The crusher with diesel engine and vibrating screen.

6.The crusher with electric motor and vibrating screen.

Features

1. Be movable and drive by diesel engine if the working site is limited

2. Deep crushing cavity, no dead zone, increasing capacity and output of the feeding

3. Large crushing ratio, uniform products particle size

4. Pad-style nesting population adjustment devices, and ease of adjustment range

5. Simple and reliable structure,low operation costs

6. The discharging size of jaw crusher can be adjusted to meet the requirements of different users

7. Low noise and less dust