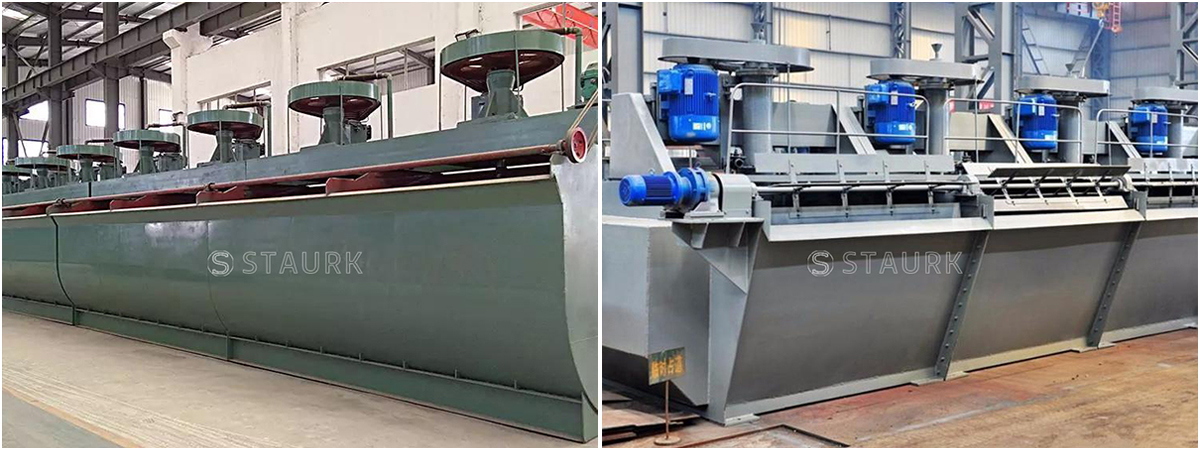

China ore flotation machine plant JJF SF BF XCK KYF flotation cell Separator

Condition:New

Origin:Henan, China

Type:JJF, Lab,XJ, XJB,A, SF, BF KYF XCF ,ECT

Another name:Flotation Separator, flotation cell

Packaging Details :A standard package in wooden boxes or containers.

Used for:Floataion plant, such as copper, gold, zinc, lead, silver, Iron, fluorite, graphite and barite, ect, it can be used to separate nonferrous metal,ferrous metal,noble metal,nonmetallic mine,chemical material and recycle mine.

China ore flotation machine plant JJF SF BF XCK KYF flotation cell Separator

Lab Flotation Machine

XFD flotation machine for lab

XFD flotation machine for lab

Mining Flotation Machine

Introduction

With the development of mining industry, investors present various requirements of the features of flotation machine. Now there are many kinds of flotation machines in staurk, such as agitator flotation machine, pneumatic flotation machine and pneumatic- agitator flotation machine. And different mineral ores have different hydrophilicity, so the final configurations greatly depend on the professional designs.

Application of Flotation Machine

Flotation machine are mainly used in mineral ore dressing plants, selecting the valuable mine from gangue. It is applicable for the separation of numerous of mineral ores, such as fluorite and talc, gold ore, copper ore, iron ore and zinc ore and so on.

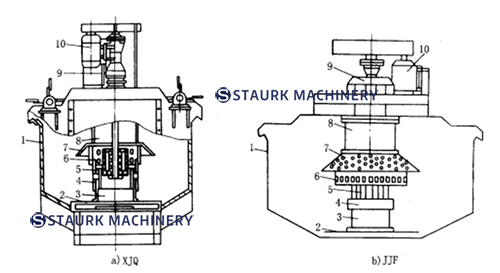

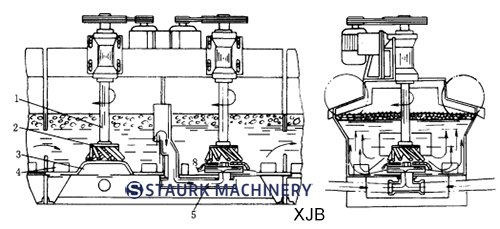

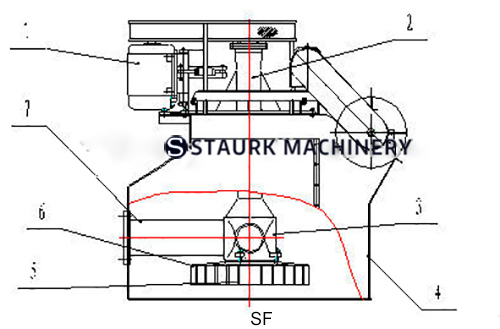

Flotation Machine drawing

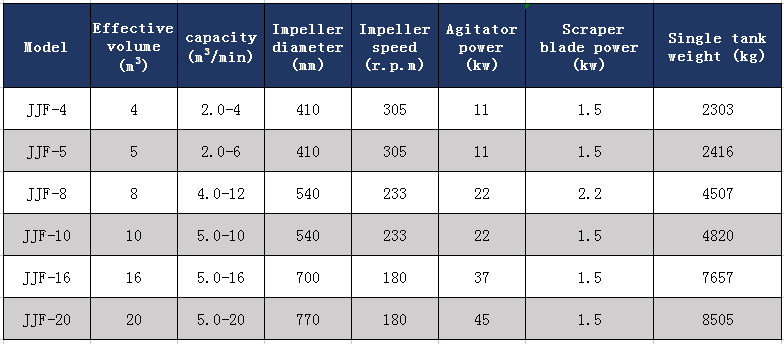

Parameter of the Mining Flotation machine

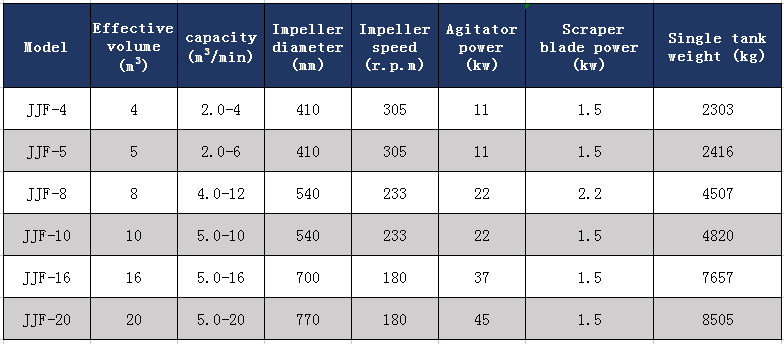

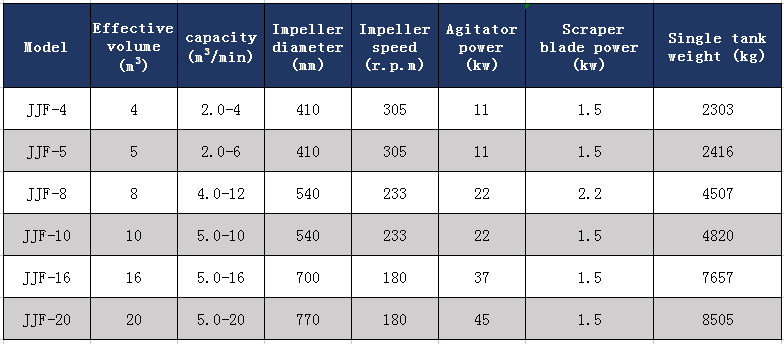

JJF FLOTATION MACHINE

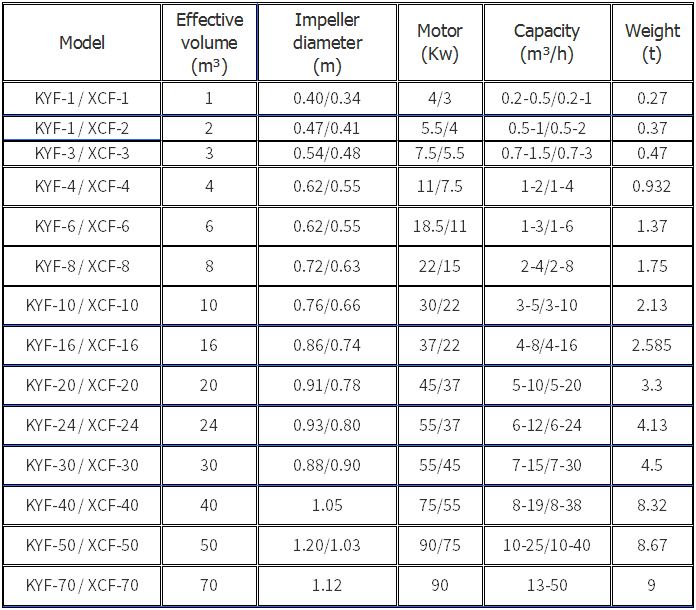

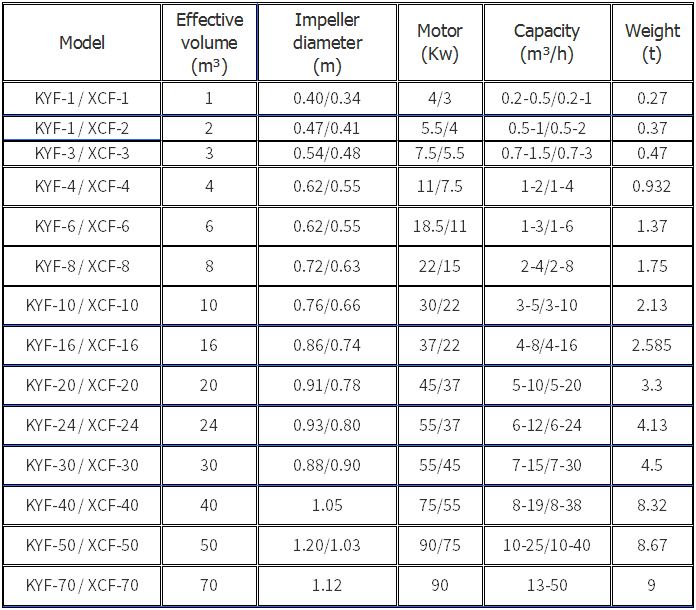

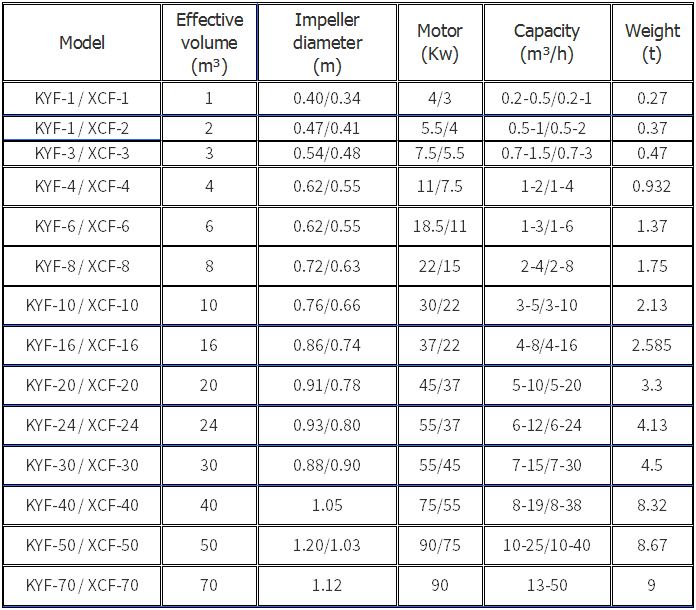

KYF / XCF FLOTATION MACHINE

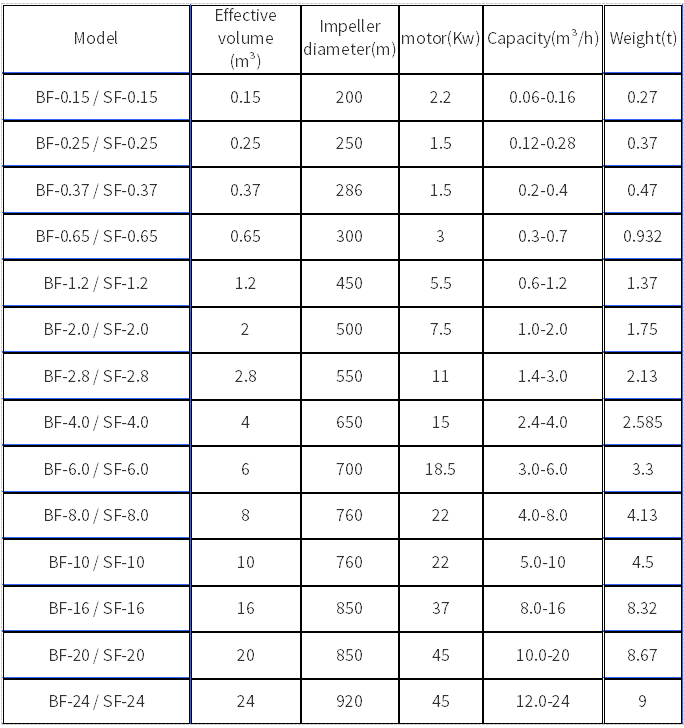

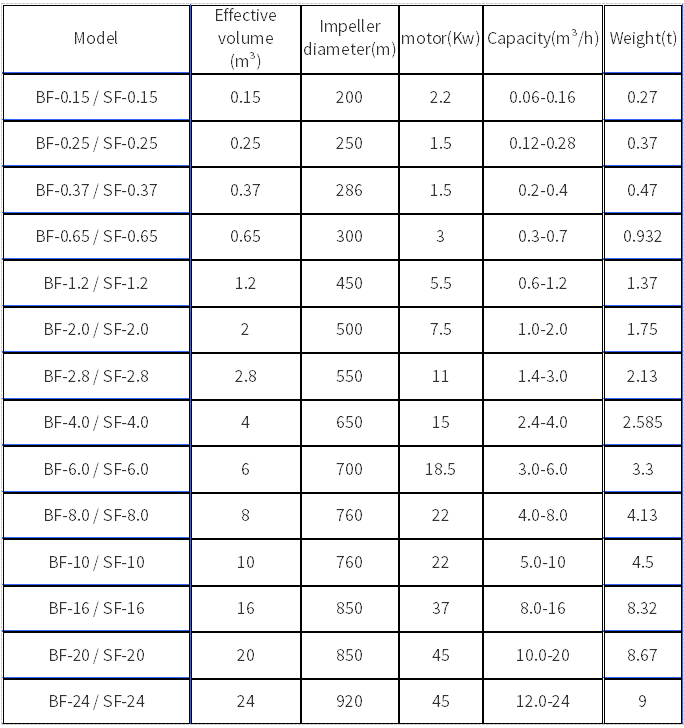

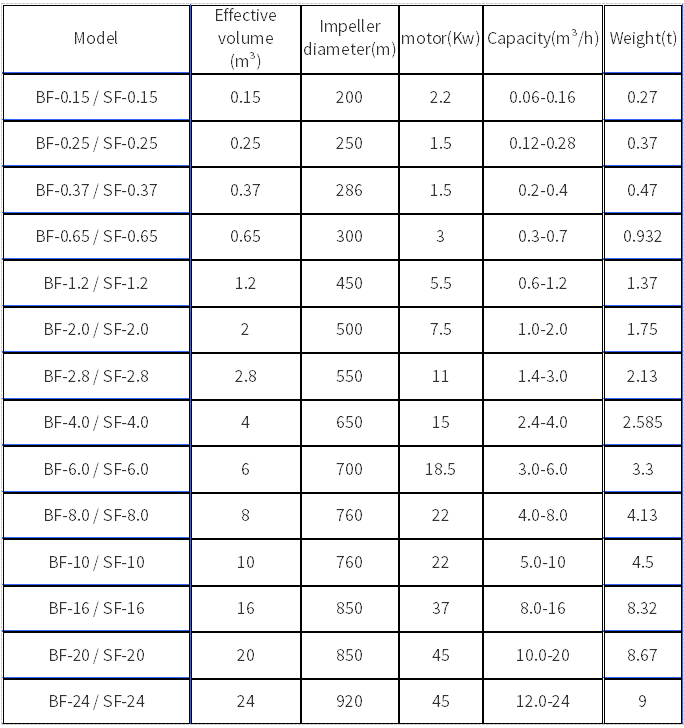

BF / SF FLOTATION MACHINE

BF / SF FLOTATION MACHINE

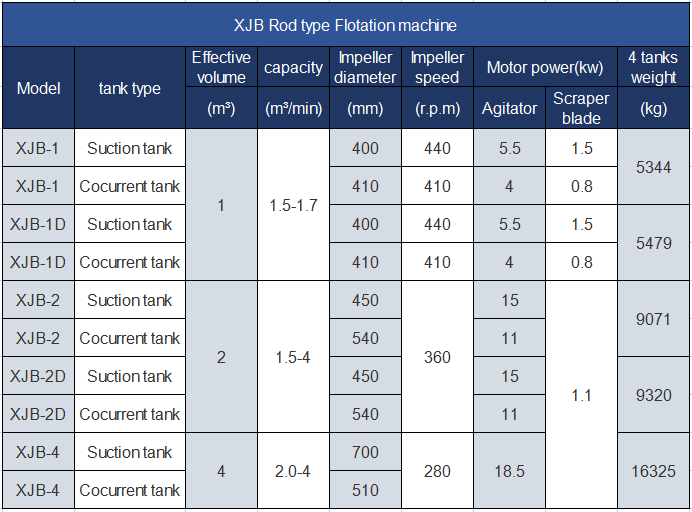

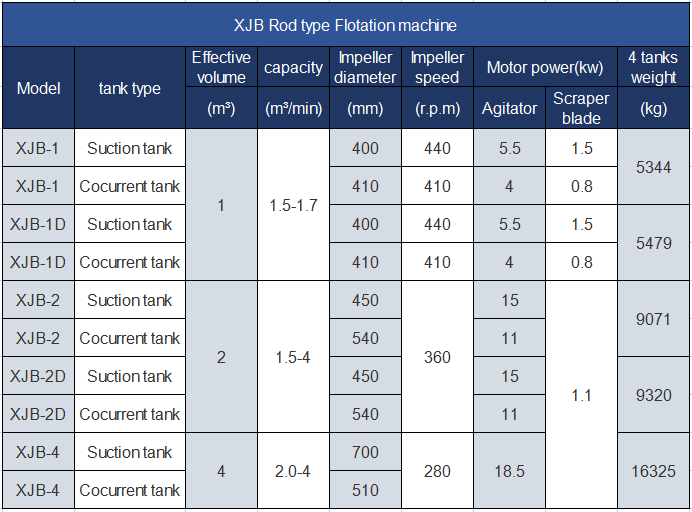

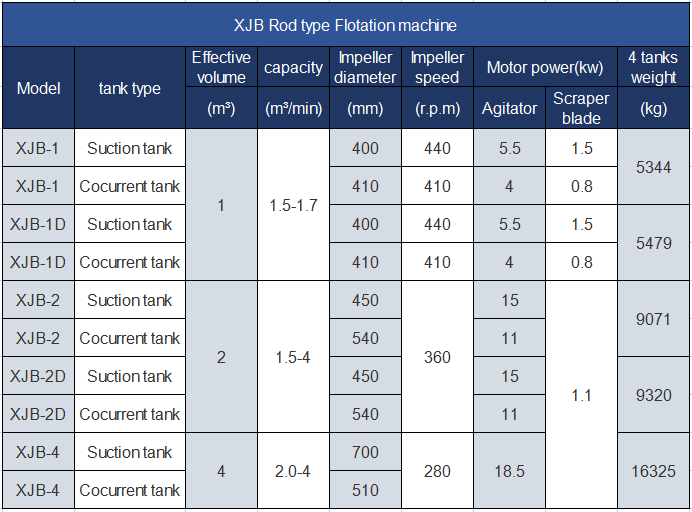

XJB / A FLOTATION MACHINE

XJB / A FLOTATION MACHINE

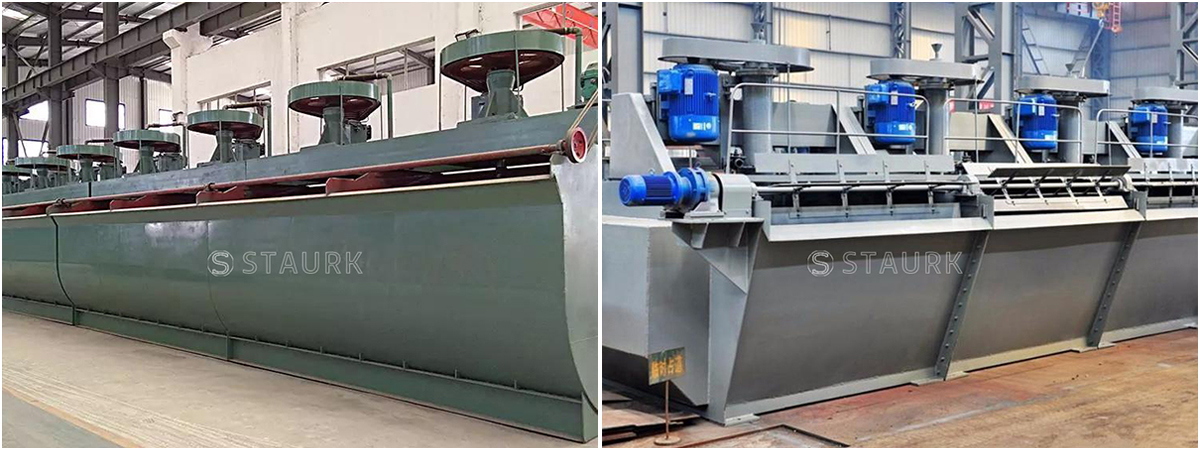

Flotation machine for sale

Flotation machine for sale

Flotation machine for sale

Features of Flotation Machine

1. Large air-absorption capacity and low energy consumption

2. Optimistic structure design & Excellent performance

3. Reasonable circulation of mineral slurry

4. Automatic control Easy to adjust

Working principle

The flotation machine is driven by the motor triangle belt to drive the impeller to rotate, which generates a centrifugal effect to form negative pressure. Floating to the surface of ore pulp to form mineralized foam. Adjust the height of the shutter and control the liquid level, so that the useful foam is scraped out by the scraper.

Sludge and reagents are fully mixed and fed into the bottom of the tank of the first chamber of the flotation machine. After the impeller rotates, negative pressure is formed in the wheel cavity, so that the slurry under the tank and in the tank enters through the lower suction port and the upper suction port of the impeller The mixing zone also allows air to enter the mixing zone along the air guide sleeve, where the slurry, air and medicament are mixed.

Under the effect of the centrifugal force of the impeller, the mixed pulp enters the mineralization zone, the air forms bubbles and is crushed, and fully contacts the ore particles to form mineralized bubbles, which are evenly distributed in the tank under the action of the stator and the turbulent plate Cross-section, and move upward into the separation zone, enriched to form a foam layer, discharged by the foam scraping mechanism to form foam.

XFD I single tank flotation machine

The XFD series single tank flotation machine for laboratory is used for flotation of a small amount of mineral samples in the industrial laboratories of geology, metallurgy, building materials, and chemistry.

2. Structural features of XFD single tank flotation machine

The XFD series flotation machine consists of the following main components

1 Machine base 2 Pallet 3 Tank body 4 Stirring part 5 Scraper part 6 Spindle part 7 Guard 8 Motor 9 Flow meter 10 Control switch 11 Scraper switch on

All parts are fastened to the body. The main shaft 1 rotates clockwise. The movement is driven by the belt pulley through the belt track. The main shaft pulley and the main shaft can achieve three different speeds. Various speeds and the position of the scraper can be adjusted by the wing nut.