China Single cylinder hydraulic cone crusher price

2024-07-09

Staurk

what is a single cylinder hydraulic cone crusher

The single cylinder hydraulic cone crusher is a bottom single cylinder hydraulic cone crusher developed and produced by our company with advanced foreign technology. It is widely used in various industries such as mining, metallurgy, and building materials, and can crush stones and rocks of various hardness. Especially in the crushing of metal mines and construction sand and gravel, it is most widely used. It is divided into standard type and short head type, which are respectively applied to medium and fine crushing operations. It has the advantages of simple structure, large processing capacity, and low energy consumption.

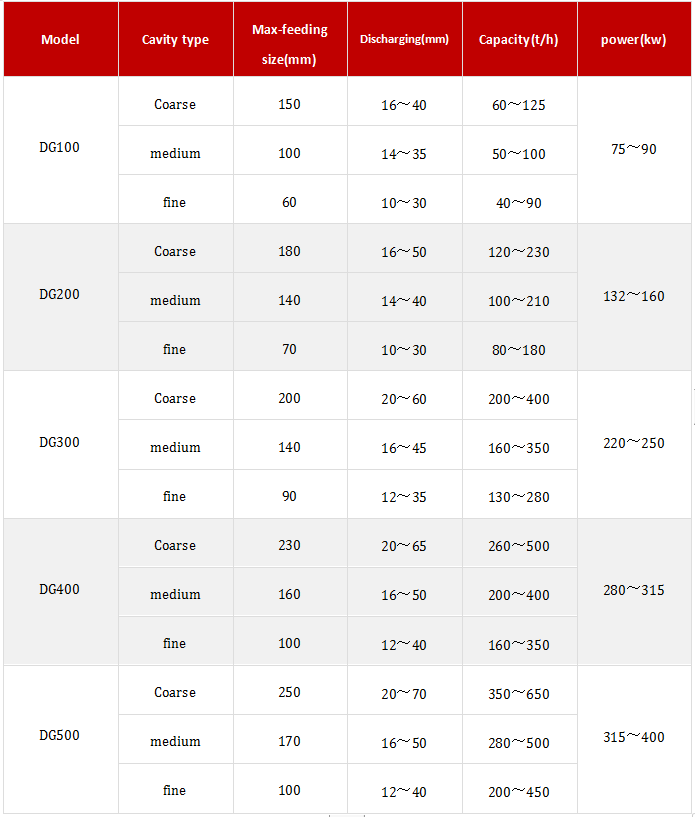

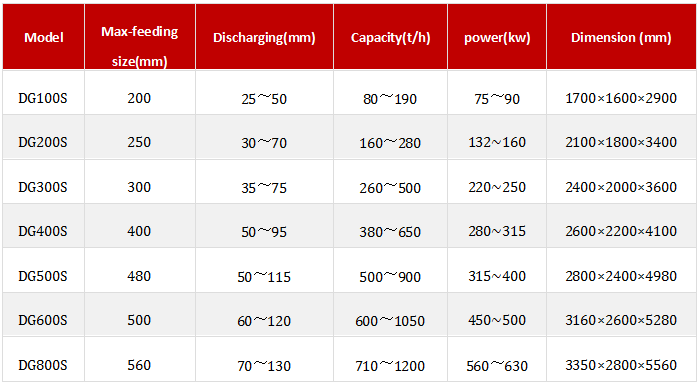

Single cylinder hydraulic cone crusher parameter

what is the main part of a single cylinder hydraulic cone crusher

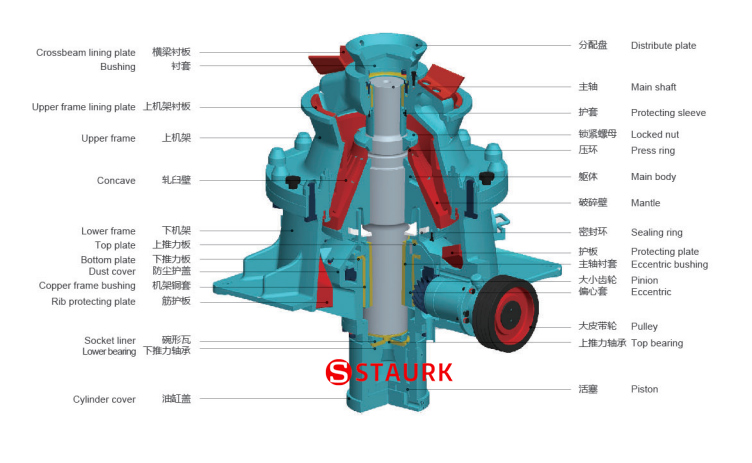

The single cylinder hydraulic cone crusher consists of seven main parts: upper frame and fixed cone, lower frame, main spindle drive cone, eccentric sleeve and sector gear, small gear and horizontal shaft, bottom hydraulic cylinder.

How does a single cylinder hydraulic cone crusher works

When a single cylinder hydraulic cone crusher is in operation, the motor drives the small gear of the crusher, and the small gear drives the large gear. The large gear component (large gear, large gear frame, eccentric steel sleeve) drives the eccentric sleeve component (eccentric cylinder sleeve, eccentric copper sleeve) and the main shaft component (main shaft, inner cone, inner cone liner plate) to revolve within the copper sleeve with the theoretical vertical line as the center. The main shaft component can achieve self rotation within the eccentric copper sleeve with the centerline of the main shaft. When the machine is running empty, the eccentric sleeve component "holds" the main shaft component and rotates together with the large gear.

When the material is added to the crushing chamber, the main shaft assembly (main shaft, inner cone) slowly rotates in the eccentric copper sleeve under the resistance of the material. The trajectory of the inner cone appears to swing back and forth in the crushing chamber, while slowly rotating. The material is crushed by the swinging inner cone. The connection between the support sleeve and the frame is tightly pressed by a hydraulic cylinder. When a metal block or other unbreakable object falls into the crusher, the moving cone of the single cylinder is supported by the bottom hydraulic piston, which plays a role in adjusting the discharge port, protecting against iron overload, and repeatedly lifting and lowering to remove blockage.

what is the advantages of single cylinder hydraulic cone crusher

1. A single cylinder hydraulic cone crusher can operate without overcrowding, but overcrowding operation is beneficial for production capacity, product fineness, and uniform wear of the lining plate.

2. The single cylinder hydraulic cone crusher is achieved through a single hydraulic cylinder lifting cone, which can easily achieve automatic adjustment of the discharge port during the production process and automatically display the size of the discharge port.

3. The horizontal force of the single cylinder hydraulic cone crusher is supported by the upper and lower ends of the vertical shaft, and the longitudinal force is supported by the floating hydraulic cylinder. The spindle structure has good stress conditions, is stable and reliable, and is not prone to adverse phenomena such as bending or breakage. The top angle of the dynamic cone of a single cylinder hydraulic cone crusher is 70 degrees, which is beneficial for processing water containing and mud containing ores

4. The single cylinder hydraulic cone crusher only needs to loosen a few bolts to loosen the fixed cone liner plate, saving time and effort.

5. The single cylinder hydraulic cone crusher has four types of eccentricities within the same crusher, and the processing capacity of the single cylinder hydraulic cone crusher can vary with the properties of the ore. It has a certain degree of flexibility.

6. The single cylinder hydraulic cone crusher is a helical helical gear with surface contact, high transmission efficiency, and uniform tooth surface wear. Long service life, only a few bolts need to be loosened to adjust the backlash.

7. The single cylinder hydraulic cone crusher provides sensitive overload and iron protection by setting the pressure of a single accumulator.

8.Under normal circumstances, it can be started with a load, which is simple and effective.

9. The single cylinder hydraulic cone crusher can be unloaded without any special requirements.

10. The single cylinder hydraulic cone crusher only needs to remove a few bolts to lift the upper frame. There are few repair parts and maintenance can be carried out from the upper part of the machine body. There are few spare parts and low maintenance costs

11. The single cylinder hydraulic cone crusher is equipped with an automatic adjustment system for the discharge port of each crusher, and multiple crushers can be centrally controlled through the central control room. The discharge port, mechanical and electrical power, and crusher pressure of each crusher can be dynamically adjusted under load, and various operating parameters, including instantaneous wear of the lining plate, can be displayed.