China roller screen coal mine stone soil mud separator - staurk

2024-09-02

Staurk

Roller screen separator, also known as soil rock separator, Mud and stone separator, soil rock separator, mountain soil screening equipment, mud and stone separation equipment, etc., can automatically adjust the operating speed according to material composition, humidity, etc.

It can be classified according to different densities, sizes, and shapes to reduce the load on subsequent sorting and crushing equipment.

Roller screen in workshop

The wheelbase and disc determine the size of the screening, and the optional sizes are very wide. The operating speed can be automatically adjusted according to the material composition, humidity, etc., effectively grading.

Roller screen video

Mobile roller screen

Mobile roller screen Structure

The machine mainly consists of: chain plate feeder, roller screen, belt conveyor, mobile frame, electronic control system, etc.

Mobile roller screen

The mobile multi-level linkage roller screen adopts an integrated overall design, using a chain plate feeder, which is easy to move, compact as a whole, has low noise, does not jam the machine, and does not block the material. This machine does not require the establishment of a foundation and can be put into production or equipped with a sprinkler system upon arrival at the site. There is no dust generated on the production site.

Roller screen Application

Separation of coarse and fine material , Clay mud , soil rock , sand and stone, large and small stone, coal and gangue, mining, aged garbage, landfill waste, construction waste separation and other material etc.

Also widely used in river cleaning, mountain stone separation, sand and stone aggregate screening, sand and stone yard pretreatment, rough stone yard, tailings treatment yard, garbage treatment yard, tunnel slag treatment, etc.

Roller screen in workshop

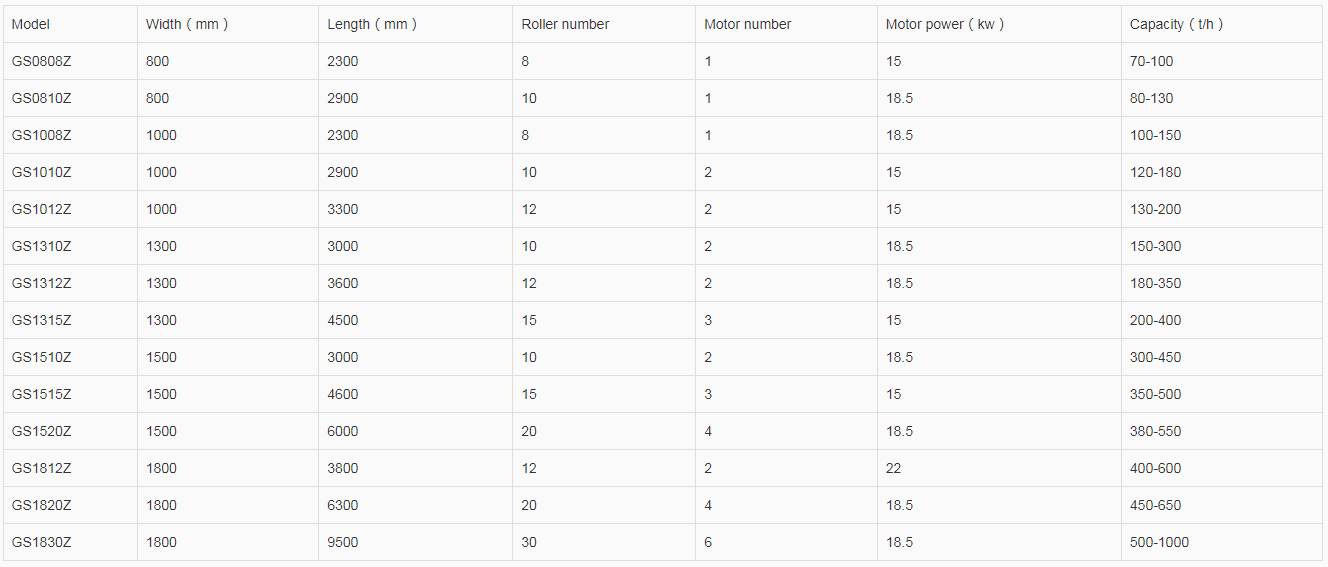

Roller screen parameter

Roller screen Features

1. High screening accuracy and efficiency, processing capacity is 4 times that of traditional drum screens of the same volume, screening efficiency is 1.5 times that of drum screens, and single machine throughput can reach up to 3000t/h.

2. The material is automatically discharged and can operate continuously. It can perform functions such as conveying, separation, and screening in different industrial and mining areas, achieving multiple uses for one machine.

3. Specially designed wear-resistant chain wheel, chain linkage, self-developed tension chain design, extremely stable operation, sturdy and durable, low noise, few vulnerable parts, easy replacement.

4. High operational stability, wide screening range, suitable for separating various types of wet and viscous materials such as mud, sand, and ore.