Graphite ore processing line flotation plant equipment China

Industrial type of graphite ore

In industry, graphite ore is divided into flake shaped and soil shaped , flake type called crystalline graphite ore , soil shaped called microcrystalline graphite ore.

Flake shaped graphite ore diameter > 1 micron meter, uaually graphite grade is low , but easily to be concentrated. usually cannot used directly , but after concentrated can be widly used.

Soil shaped graphite ore diameter < 1 micron meter , cannot be easily concentrated, usually by grinding machine , then directly used.

Flake shaped graphite ore processing line

Mineral composition :Graphite, plagioclase, tremolite, diopside, quartz, mica, chlorite, pyrite, calcite, etc

Processing methord:

Graphite ore processing line flotation plant

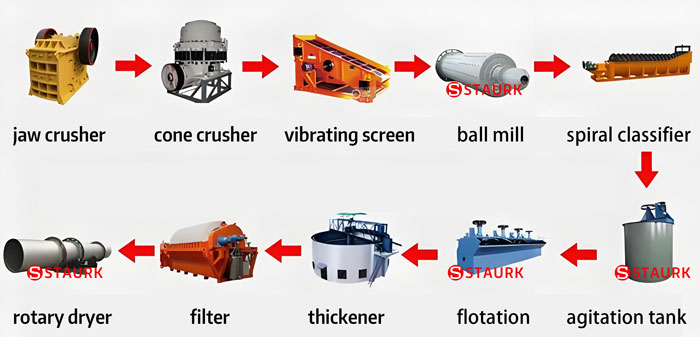

1.Flotation : flow chart as above

1.1Flotation machine working steps

1. Crushing: The graphite ore is initially crushed using crushing equipment such as

jaw crusher,

cone crusher, and

hammer crusher to achieve the initial dissociation of graphite and gangue minerals. The crushing process usually adopts three-stage open circuit, two-stage open circuit or one-stage open circuit process. Small mines that process weathered ore can directly grind without crushing

2. Grinding: During the grinding stage, a

ball mill,

rod mill, or agitator mill is used to dissociate graphite monomers or associated bodies. In order to protect large flake graphite, a multi-stage grinding process is often used to ensure early selection of large flake graphite

The ore after grading and grinding is classified by a

cyclone and a spiral classifier, and qualified particle size products are separated according to particle size

3. Slurry adjustment:

Slurry adjustment is an important process in mineral purification and sorting, which reduces the surface tension of graphite and other minerals by adding chemical reagents such as kerosene, diesel, and other collectors and foaming agents, making them easier to separate

4. Flotation:

Coarse selection: The ground ore is subjected to coarse selection, and most of the target minerals are separated through physical and chemical methods.

Sweeping and selection: The tailings after rough selection are discarded after 1-2 sweeps, while the coarse concentrate is subjected to multiple regrinding and selection to further improve the purity and quality of graphite. During the selection process, multi-stage grinding and multi-stage selection techniques are often used to protect graphite flakes from damage

Intermediate ore processing:

During the flotation process, a large amount of intermediate ore will be generated, and if not treated, the recovery rate will be reduced. The processing methods of Zhongkuang include centralized return, sequential return, and separate processing to ensure efficient utilization of resources

1.2Flotation agents

Flotation collectors: including kerosene, diesel, heavy oil, sulfonic acid esters, sulfuric acid esters, phenols, carboxylic acids, etc;

Flotation foaming agents: pine alcohol oil, No. 4 oil, ether alcohol, butyl ether oil, etc;

Flotation adjuster: lime, sodium carbonate;

Flotation inhibitors: lime, water glass

2.Gravity plant :

Mainly using a

shaking table to remove pyrite and pre extract large flake graphite

Graphite ore shaking table

Graphite ore shaking table

Soil shaped graphite ore processing flow chart:

Raw material - primary crusher - secondary crusher - dryer - grinding - screen - package.

Parameter of the Graphite ore processing line