Rod mill China steel slag sand grinding making machine

Rod mill video:

Rod mill

Rod mill is a mill in which the grinding body loaded in the cylinder is a steel rod. Rod mills are generally of wet overflow type, which can be used as primary open-circuit grinding, and are widely used in primary grinding of artificial stone sand,

sand making machine, mineral processing plants, and power departments of chemical plants.

Rod mill in grinding process

In the grinding process, the grinding medium is in line contact with the ore, which has a certain selective grinding effect. The particle size of the product is relatively uniform, and there is less over-crushing. When used for rough grinding, the processing capacity of the rod mill is greater than that of the ball mill of the same specification.

MBS1830 rod mill in site 1

Rod mill application

It is widely used in the first-level grinding of artificial stone sand, mineral processing plants, chemical plants and electric power departments.

Tips & precautions during use

1. Feed evenly

Uniform feeding is an important operation to ensure the highest output and stable quality (fineness) of the rod mill.

The fineness of the product becomes thicker, which generally means that the feeding amount is too large;

The fineness of the product becomes thinner, which means that the feeding amount is less

According to this principle, adjust the feeding amount in time.

2. Add steel rods in time

When will use a rod mill not a ball mill ?

1.When heavy separation or magnetic separation of tungsten tin ore and other rare metal ores, rod mills are often used to prevent excessive crushing;

2.In the second-stage grinding process, rod mills are generally used as the first-stage grinding equipment, which has larger production capacity and higher efficiency.

3.When processing softer or less hard ores, rod mills can be used to replace short-head cone crushers for fine crushing, which is not only simple in configuration, but also low in cost, and simplifies dust removal in the workshop.

Steel rod for rod mill

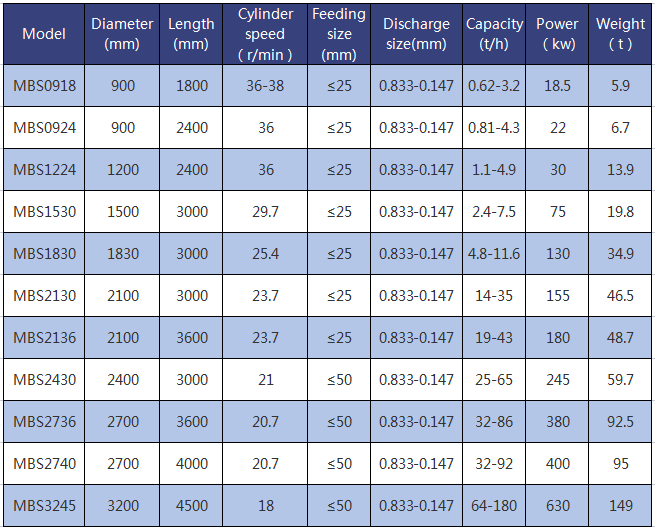

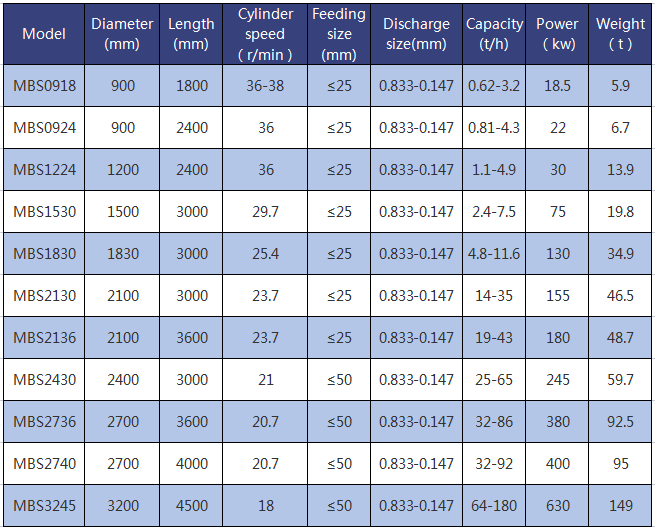

Parameter of the Rod mill

The difference between rod mill with ball mill

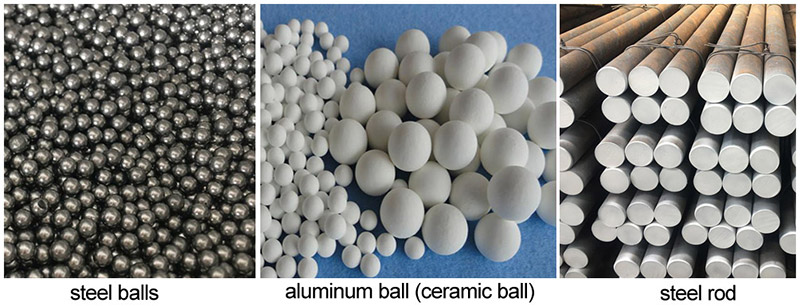

1. Analysis of grinding media

The difference in grinding media is the main difference between the two

Rod mill: steel rods with a diameter of 50-100mm are used as grinding media, and the steel rods are in line contact

Ball mill: steel balls are used as grinding media, and the steel balls are in point contact

The steel balls of the ball mill are in point contact, and the steel rods of the rod mill are in line contact, so the working characteristics of the two are obviously different.

2. Application

Ball mill are more than fine grinding, rod mill are mostly used for rough

Rod mill: Mainly used in rough grinding. When the product size is 1-3mm, the processing capacity of the rod mill is greater than that of the ball mill of the same specification.

Ball mill: When used for fine grinding and the product size is less than 0.5mm, the grinding effect of the ball mill is greater than that of the rod mill of the same specification.

3. Performance analysis

Rod mill: The process characteristic of the rod mill is that the product is coarser, but the particle size is uniform, contains less coarse particles and sludge, and is lighter over smashing.

Ball mill: The performance characteristics of the ball mill are high production capacity, strong adaptability to materials, high degree of fineness of materials, and fine discharge granularity.

4.Analysis of medium filling rate

The medium filling rate refers to the percentage of the grinding medium in the volume of the mill. For different grinding methods, mill structures, operating conditions and media shapes, the media filling rate has a suitable range, too high or too low will affect the grinding effect.

Ball mill: filling rate is 40%-50%

Rod mill is 35%-45%

The packing rate of the self-mill is 25%-40%, and the packing rate of the gravel mill is about 43%.

Rod mill Working principle

Similar with ball mill working principle , When the cylinder rotates, the grinding medium (steel rod) installed in the cylinder is lifted to a certain height as the cylinder rotates under the action of friction and centrifugal force, and then throws down at a certain linear speed, so the cylinder is The materials inside are impacted, ground and squeezed to make them crushed.

Rod mill features

1. Energy saving

Older equipment saves more than 40% of power. The particle size of the product is more uniform, and there are fewer coarse particles and sludge. Compared with the particle size characteristics of the rod mill product and the ball mill product, the particle size characteristic curve of the rod mill in the open-circuit operation is almost the same as that of the ball mill in the closed-circuit operation.

2. The discharging granularity is more uniform and the output is higher

The use of high-quality controllable feeding and discharging rod mill technology, combined with the actual user’s grinding materials, is equipped with a suitable grinding body, which changes the surface contact of the traditional ball mill to line contact, so that the discharge particle size of the rod mill is more uniform and the output is higher. High, suitable for ores with different hardness (Mohs hardness 5.5~12).

3. Adjustable discharge fineness

The granularity of the discharging material can be changed by simple adjustment. The fineness control device is built-in, and the discharging device can be added with a screening device. The two checks ensure that neither over-grinding nor unqualified products are mixed into the finished product. The particle size characteristics of rod mill products are related to the ore crushed by rod mills. When the rod hits the ore, it first strikes the coarse particles, and then grinds the smaller ore particles, thereby reducing the risk of over-crushing. When the rod rotates and rises along the liner, the coarse particles are sandwiched in between, like a rod sieve, allowing fine particles to pass through the gap between the rods. This is also conducive to crushing the coarse particles and making the coarse particles concentrated in the grinding medium. The place to hit. Therefore, the rod mill product is more uniform, and the over-crushing is lighter.

Lab rod mill

China lab rod mill for sale small mini roller drum grinding mill price

The lab rod mill is suitable for the preparation of gold ore analysis samples, and the prepared samples have good uniformity. It adopts mechanical sampling, cleaning, dust removal, low silica dust, easy operation and stable quality. This machine is also suitable for preparing other rock mineral geological samples.

This machine is a dry and wet prototype grinding machine in the laboratory. It has a compact and novel structure, simple transmission, few rubber rollers, high grinding efficiency, convenient operation, safe and reliable. It can be used for metallurgy, building materials, geology, chemical, coal and other experimental research units and concentrators to conduct ore selectivity research or for other industrial departments to grind small amounts of materials. Especially the best ideal equipment for grinding gold samples.

1. Drum specifications: 4 drums, 8 drums, 12 drums, 16 drums, 24 drums, 50 drums, etc., can be customized

2. Drum diameter: Φ108, Φ127, Φ146, Φ166

3. Feeding size: -2 mm

4. Discharge size: 180-400 mesh

5. Roll diameter and speed: Φ130mm, 160r/min

Technical characteristics:

1. The crushed sample is mainly based on the grinding force. The sample is crushed in the sample cylinder and mixed by itself. After the sample is crushed, it is not necessary to perform heavy operations such as sieving and mixing one by one.

2. The automatic timer only counts the grinding time at the time, the time of the power outage is not counted, and it will automatically stop when grinding reaches the specified time. Because it is equipped with a protection device for automatic shutdown of fault overcurrent, no personnel is required during grinding Guarded by the machine.

3. The machine is equipped with tube taking, sampling, cleaning and dust exhaust devices, which reduces the labor intensity of the operator and the hazard of silica dust.

4. Change the technology of rod hammer to rod mill in the past; use exhaust fan and rubber roller to improve working conditions.

5. Mechanical cleaning with a brush and air pressure to clean and reduce mutual contamination of samples; the dust generated by the cleaning is concentrated in the small hood before it is diffused.

6. The lab rod mill adopts a cross-arm micro-elastic locking structure, which is securely locked, easy to operate, and does not leak samples.

7. Open mechanical cleaning with brush and air pressure to avoid contamination of samples. The dust generated by the cleaning will be discharged in a small hood before it is diffused, which greatly reduces the hazard of dust to the human body.