Batch Ceramic ball mill for feldspar glass China staurk

Ceramic ball mill liner

Ceramic balls

Ceramic balls

Introduction:

The ceramic ball mill is mainly used for the mixing and grinding of materials, the fineness of the product is uniform, and the power is saved. Both dry and wet grinding can be used. The machine can adopt different liner types according to production needs to meet different needs. The fineness of the grinding operation is controlled by the grinding time. The electric machine is started by self-coupling decompression to reduce the starting current. Its structure is divided into integral type and independent type.

Ceramic ball mill

Ceramic ball mills are widely used in the grinding of electronic materials, magnetic materials, ceramic glaze slurry, ink pigments, non-metallic minerals, glass, pigments, coatings, electromagnetics, refractory materials and other materials.

It can also be used for the grinding of chalk, gypsum, bricks, limestone , feldspar, silica, quartz, ceramics, clay, glass, rubber, plastics, etc.

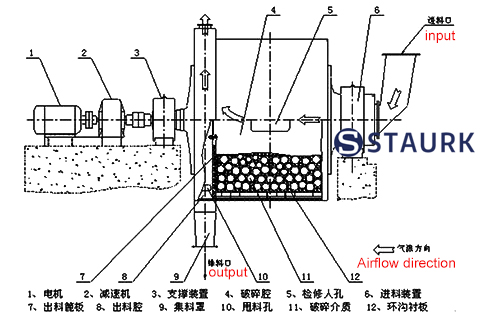

Structure:

1. Motor

2. Reducer

3. Support device

4. Grinding cavity

5. Overhaul manhole

6. Feeding device

7. Outlet grates

8. Outlet cavity

9. Aggregate hood

10. Spoiler

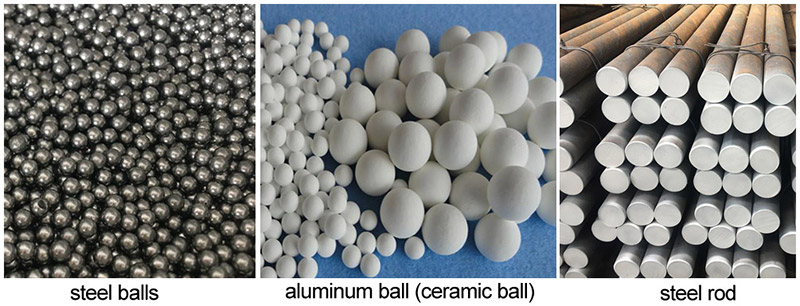

11. Grinding media

12. Ring groove liner

The ceramic ball mill is generally a horizontal cylindrical rotating device, which is composed of a feeding part, a discharging part, a rotating part, a transmission part (reducer, small transmission gear, motor, electric control) and other main parts.

The difference between ceramic ball mill and ball mill:

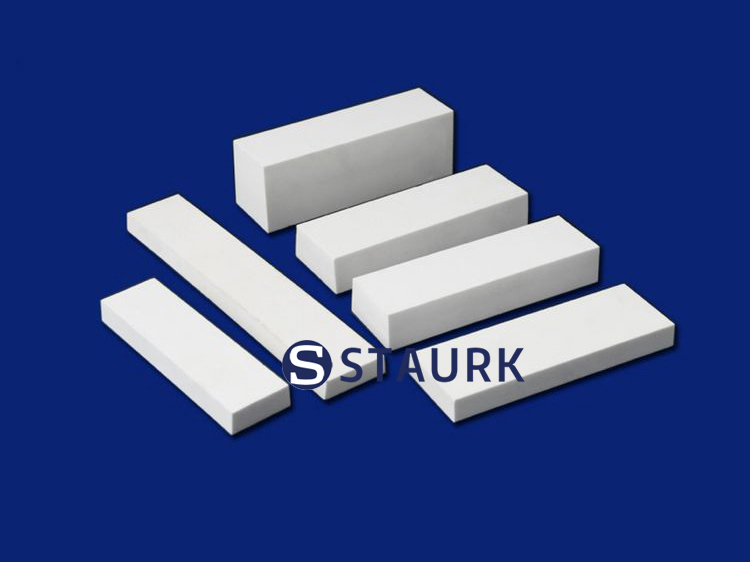

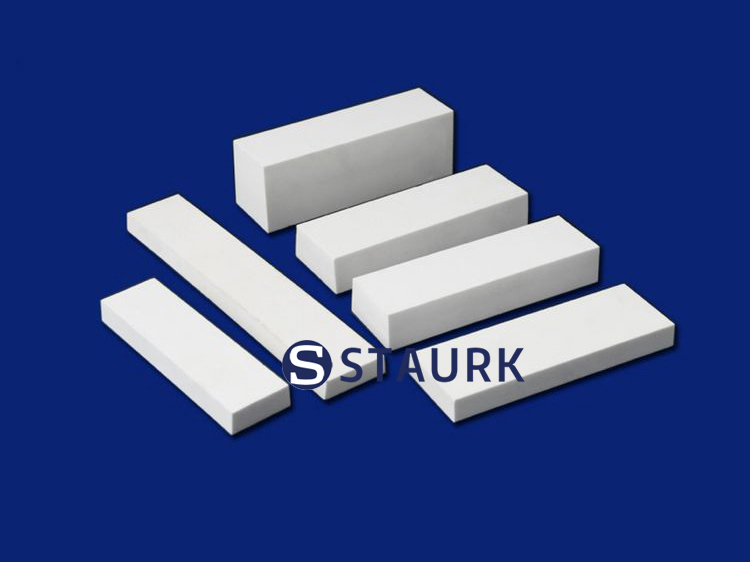

Ceramic ball mill liner

The biggest difference of the ceramic ball mill lies in the material of the liner and the grinding media.

Ceramic ball mill, a ball mill with wear-resistant ceramic liner, used in conjunction with ceramic balls, has high grinding precision and less metal impurities, which not only improves the service life of the equipment and the purity of materials, but also expands the application range, from high-purity silica to oxidation Special ceramics of aluminum and zirconia, from medicine to glaze, can provide grinding function in all kinds of medium crushing, fine crushing and ultra-fine crushing operations.

The ceramic wear-resistant liner of the ball mill includes three parts: the straight plate of the ball mill, the ceramic guard plate and the bolt. This design has a simple structure, convenient installation and easy maintenance.

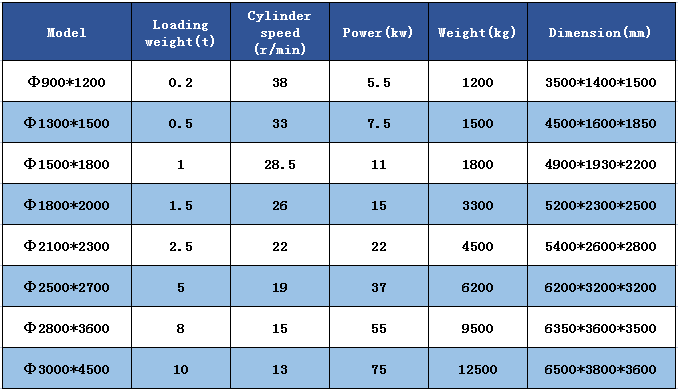

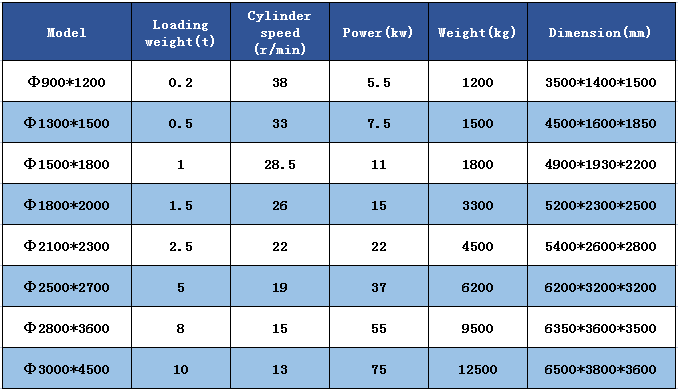

Parameter of the Ceramic ball mill

Features

1. The type of liner can be changed

Ceramic ball mills can use different liners according to the different materials produced to meet different needs.

2. Large scope of application

In addition to grinding materials, ceramic ball mills can also be used for medium crushing, fine crushing and ultra-fine crushing of materials in large stone factories, and can process various ores.

3. Good energy saving

The ceramic ball mill can be started from decompression during work, reducing the starting current, so it is more energy-saving.

4. Uniform product size

Because the discharge port of the ceramic ball mill has a grating to control the particle size of its discharge, it is difficult to discharge oversized materials from the discharge port. Therefore, the content of large materials in the product is small, and there are many material particles that meet the requirements.

5. Small footprint

Compared with other ball mills, the ceramic ball mill has a shorter length, so it occupies a small area, which can reduce the cost of land input.

6. Stable operation

The main transmission device of the ceramic ball mill adopts a closed gear, so the stability of the transmission is enhanced.