China 3PC Three disc magnetic separator Tungsten Tin Belt

Three disc magnetic separator also called Three disc belt magnetic separator , is an important equipment for selecting weak magnetic minerals and rare metal ores. Suitable for the separation of various magnetic mineral mixtures, according to the magnetic differences of minerals, different magnetic fields of different strengths can be formed by adjusting the excitation current of each level of disk to efficiently separate minerals. The induction distance between each level of disk and the ore particles can also be adjusted to obtain different magnetic field induction strengths, achieving one-time separation of multiple minerals.

Three disc magnetic separator types

Three disc magnetic separators are divided into three models: CP3-500, CP3-600, and CP3-600S

Three disc magnetic separator application

Suitable for dry selection of various metallic and non-metallic minerals with magnetic differences, such as titanium ore, rare earth ore, tungsten ore, tin ore, chromite ore, niobium tantalum ore, limonite, rare earth ore, zircon, rutile, monazite, rhodochrosite, lapis lazuli, feldspar, quartz, etc., for iron removal and separation purification.

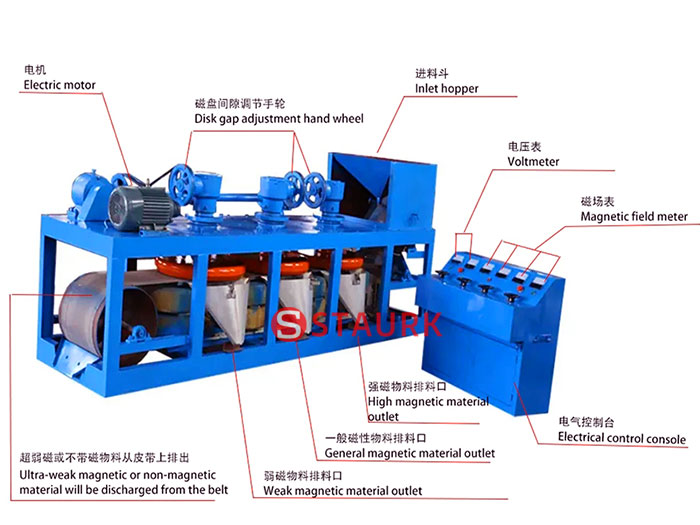

Three disc magnetic separator structure

The main unit of the three disc belt magnetic separator consists of a feeding device, a weak magnetic drum, a transmission part, a material conveying device, a magnetic disk, an electromagnetic system, a frame, etc. The electronic control part consists of components such as control, voltage regulation, rectification, and instrumentation. It has the advantages of compact structure, stable performance, easy installation, and convenient use and maintenance.

Three disc magnetic separator advantages:

1.Can separate multiple minerals such as strong magnetic, weak magnetic, non-magnetic, etc. at once

2.Single machine equipment has the advantages of reasonable structure, small footprint, and simple operation and maintenance

3.Adjustable magnetic field strength, adjust the magnetic field according to different raw materials to achieve sorting effect

4.Long utilization rate, good sorting efficiency, suitable for dry operation in water scarce mining areas

Parameter of the Three disc magnetic separator

|

Item |

Name |

Specification |

|

1 |

Model |

3PC-500 |

3PC-600 |

3PC-600S |

|

2 |

Magnetic intensity |

17000GS |

18000GS |

20000GS |

|

3 |

Disk number |

3 |

3 |

3 |

|

4 |

Disk diameter |

500mm |

600mm |

600mm |

|

5 |

Disk revolution |

22-38r/min |

22-38r/min |

22-38r/min |

|

6 |

Excitation coil |

4sets |

4sets |

4sets |

|

7 |

Motor power |

1.1KW |

2.2KW |

2.2KW |

|

8 |

Coil temperature |

65ºC |

65ºC |

65ºC |

|

9 |

Coil current rating |

1.1-1.8A |

1.2-1.9A |

1.2-2.2A |

|

10 |

Feeding width |

210mm |

300mm |

300mm |

|

11 |

Feeding size |

≤ 2mm |

≤ 2mm |

≤ 2mm |

|

12 |

Dimension size(mm) |

2800×800×1220 |

3150×900×1250 |

3200×900×1160 |

|

13 |

Capacity |

100-500kg/h |

120-800kg/h |

500-800kg/h |

|

14 |

Weight: |

1900kg |

2200kg |

2400kg |

|

15 |

Control Cabinet |

Included |

Included |

Included |

Three disc magnetic separator installation

1. For new installations or installations after relocation, routine inspections must be conducted on the mechanical and electrical parts, paying attention to whether each part is damaged, loose, damp, etc. Place the magnetic separator horizontally.

2. Install the electrical control console in a convenient location for operation and observation, and connect the ground wire as usual.

3. Connect a 25 ampere fuse to the knife switch outside the console, and connect the black wire in the four core power cable to the neutral wire. Connect the wires between the host and the console according to the same number.

Three disc magnetic separator installation

1. Dry materials are sieved and loaded into the feeding hopper. Particle size requirement<2 millimeters

2. Adjust the disk working gap according to the ore type, particle size, and sorting requirements.

3. Close the knife switch to supply power to the control panel.

4. Turn on the motor and magnetic field switch. Adjust the voltage regulator to the appropriate current

5. Open the feeding valve to evenly distribute the material onto the conveyor belt.

6. Stop feeding before stopping the machine.

When there are not many magnetic minerals in the raw material, the feeding layer should be thinner to improve the recovery rate. When there is a high content of magnetic minerals, the feeding layer can be

Make it thicker.

When the working gap of the disk is constant, changing the current can adjust the magnetic field strength; Adjust the disk operation when the current is constant

Gap, adjustable magnetic field strength.

9. Use weaker magnetic fields for processing and selecting magnetic minerals with strong magnetism, and use stronger magnetic fields for processing and scanning minerals with weak magnetism

Magnetic field.

10. The size of the disk working gap depends on the particle size of the processed ore and the beneficiation requirements. When processing coarse grades, it is larger

The level of detail is smaller; When scanning and selecting, reduce the gap to improve the recovery rate. When selecting, increase the gap to improve the grade of magnetic products, but at the same time, increase the current to compensate for the reduced magnetic field strength caused by increasing the working gap of the disk. Require clear space between the disk teeth and the mineral material on the conveyor belt surface.

11. When adjusting the machine and performing beneficiation operations, comprehensive consideration should be given to factors such as grade, recovery rate, and processing capacity.

Notes for attention

1.When the magnetic separator is in operation, strong magnetic tools and objects should not be placed near the magnetic system, and operators should not touch rotating parts and wire joints to avoid safety accidents.

2.When adjusting the working gap of the disk, it is necessary to maintain an appropriate distance between the disk teeth and the conveyor belt to avoid damaging the conveyor belt.

3. During the operation of the magnetic separator, do not let the motor run in phase loss. When abnormal sound is detected during motor operation, the machine should be stopped in time to check the power supply circuit.