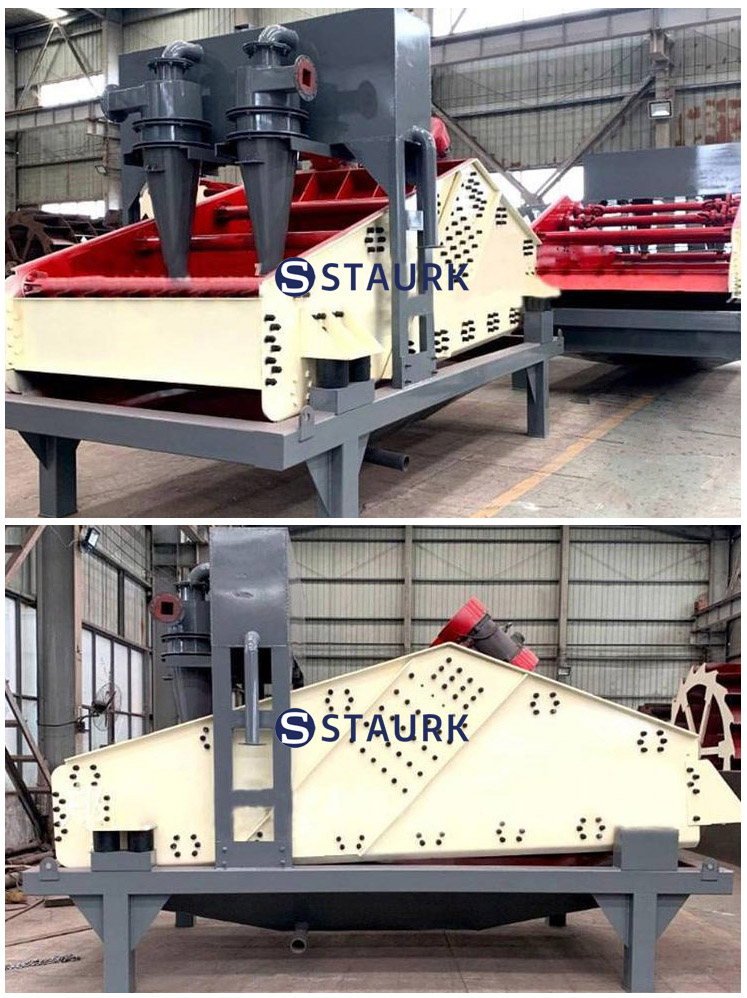

Dewatering Screen is widely applied for dewatering, desliming, deintercalation, which can be used to sand and stone washing plant, coal preparation plant, sludge recycling, mineral processing plant, tailings dry discharge and more.

So it is also called sand dewatering screen, mining dewatering screen, coal slime dewatering screen, tailings dewatering screen, high frequency dewatering screen etc.

Application

Dewatering Screen can be used for: dewatering tailings Tailings, sewage, coal slime, mining, washed sand, mud treatment, soil repaire, fine sand etc.

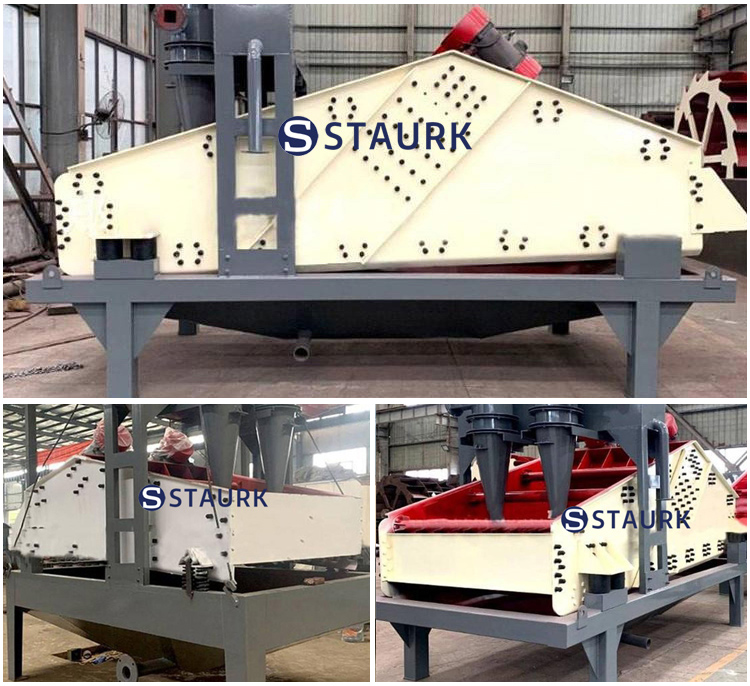

Sand dewatering screen

To wash sand with water, the sand dewatering screen is often used in sand washing machine plant and wet sand production line , or be used alone.

After the sand washing machine and dewatering screen plant , which usually can achieve a reasonable particle size ratio and reduce the mud content to less than 0.7%.

Tailings Dewatering Screen

Widely used in tailings dry discharge and tailings dewatering compared with mining thickener etc.

Especially suitable for fine-grained minerals, usually working together an hydrocyclone ,as a tailings dry discharge recovery system plant machine.

High frequency dewatering screen

It is suitable for high-frequency and high-vibration-strength material.

The dewatering screen can make waste materials into environmentally friendly things, and be reused.

Coal slime Dewatering Screen

It can be used to recover coal slime with a particle size of less than 9mm. It is a special equipment for coal , coarse and other fine materials.

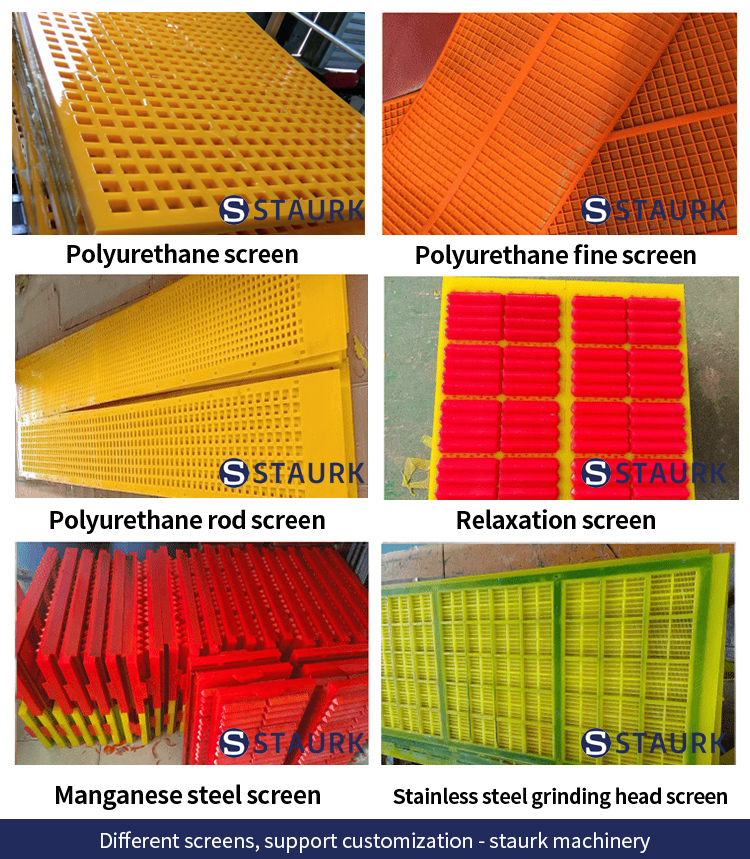

The screen or sieves of Dewatering screen machine

Polyurethane screen panel is made of polyurethane materials. It mainly used for miningmineral processing, grading, dehydration and other screening machines replace metal sieve (mesh) of a new product. Mainly used in coal, iron ore, copper, gold and other ores grading, screening, dewatering and other places. It can separate and screen almost all of materials from coarse stones to fine materials and ideal for both dry and wet materials.

Application of Screen or sieves

Wear-resistant sieve plates of various ordinary vibrating screens, circular vibrating screens, linear vibrating screens, bar wire screens, relaxation screens, sintered cold ore screens, etc.

4. Polyurethane screen (PU)panels with high screening ratio, big capacity,long service life and no blocking. 5. Widely used, less replacement parts.

Features - screen or sieves of Dewatering screen machine

1. Good wear resistance and long service life, more than 10 times that of metal screen (sieves), 3-5 times that of ordinary rubber sheets, and 2-3 times that of stainless steel screen (sieves).

2. The ore consumption per ton is lower than the metal screen

3. Good moisture resistance and wear resistance.

4. Shock absorption and noise reduction, more than 20bB times lower than metal screen (sieves) plate (net).

5. Automatic cleaning, due to the characteristics of secondary vibration of polyurethane, it does not block holes, and the screening efficiency is high.