Mining washing machine Rotary scrubber washer China gold

Application

The Mining washing machine is widely used for pre washing sediment in ore beneficiation with high mud content, and can be used for various difficult to wash large ores such as stirring, washing, separation, and desliming of minerals.

Clean the mud containing ore before the implementation of the beneficiation process to improve the subsequent beneficiation indicators.

Working principle

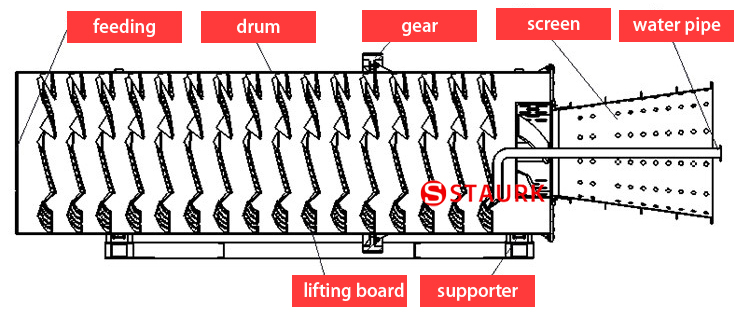

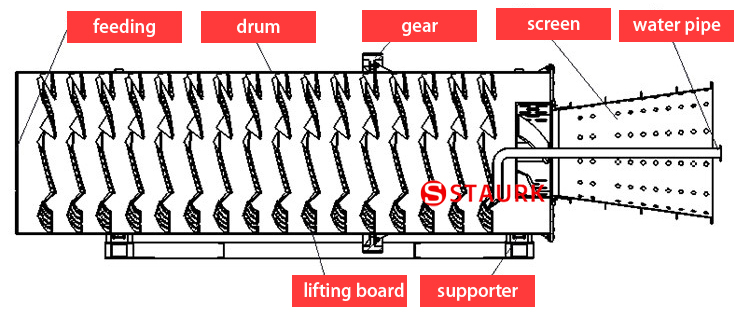

Mining washing machine is mainly composed of a washing drum and a double-layer drum screen connected to the end of the drum. The front section has no holes and is used for soaking and crushing ores, while the rear section has holes for separating mud and rock.

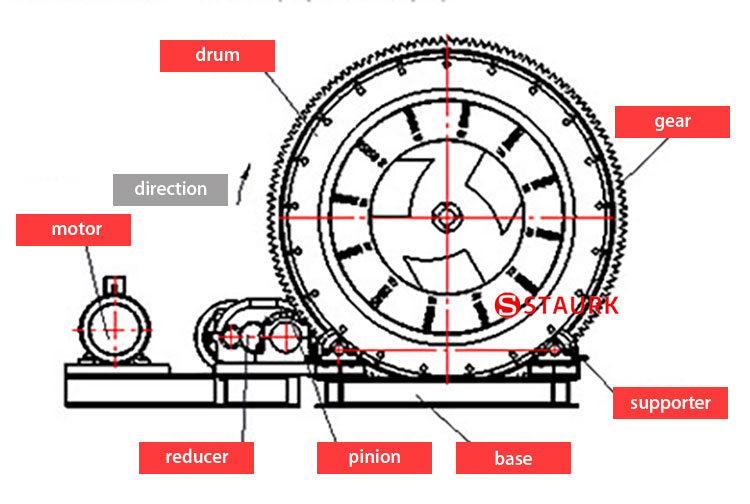

The cylinder is supported horizontally by four rollers on two steel rings, and is driven to rotate by a small gear through a gear ring located in the middle of the cylinder. A ribbed lining plate is installed on the inner wall of the cylinder, arranged in a spiral pattern with the pitch increasing towards one end of the cylinder screen, used for stirring and pushing the material out.

Structure drawing

Mining washing machine Rotary scrubber washer drawing 1

Mining washing machine Rotary scrubber washer drawing 2

Parameter of the Mining washing machine

|

Model |

Max-feeding size(mm) |

Capacity(tph) |

Drum dimension(mm) |

Power(kw) |

Weight(t) |

|

ST1030 |

80 |

20-30 |

Φ1000*3000 |

15 |

3.8 |

|

ST1230 |

100 |

30-50 |

Φ1200*3000 |

22 |

4.7 |

|

ST1540 |

160 |

50-80 |

Φ1500*4000 |

30 |

6.9 |

|

ST1840 |

200 |

80-120 |

Φ1800*4000 |

37 |

13.2 |

|

ST2060 |

210 |

100-140 |

Φ2000×6000 |

55 |

14.8 |

|

ST2080 |

210 |

100-140 |

Φ2000×8000 |

55 |

15.5 |

|

ST2250 |

230 |

120-160 |

Φ2200×5000 |

55 |

15.9 |

|

ST2460 |

240 |

200-300 |

Φ2400×6000 |

55 |

26 |

Flow chart for mining washing :

Mining washing machine can divide the washed raw materials into two types:+40mm and -40mm, - 40mm materials can be further cleaned using a

sand washing machine, which can divide the raw materials into two types:+2mm and -2mm.

The high efficiency of ore washing can reach around 98%, and this type of composition is the most effective way for difficult to wash ores.

Benefits of mining washing machine:

1. Large processing capacity and strong ore washing ability

The drum washing machine has low operating costs, with a single processing capacity of 200-300 tons per hour. The mineral content cleaned is less than 0.5% mud and less than 2% water; The isolation of the impeller drive bearing device from water and water receiving materials greatly avoids the occurrence of bearing damage caused by immersion in water, sand, and pollutants.

2. High ore washing efficiency, graded particle size of finished products

The ore is fully soaked at the front end of the drum washing machine, and the separation of ore and mud is achieved at the back end. The entire equipment has a significant water-saving effect, with a washing efficiency of up to 98%; The rotary drum is equipped with a single-layer or double-layer circular sieve to obtain two or three different specifications of sand and stone products.

3. High quality components with long service life

The cylinder body is made of thickened steel plates, heavy-duty gears, and pulleys. Except for the finished material stacking belt conveyor, all systems are integrated into a single frame, ensuring the integrity of the equipment while leaving moderate maintenance and inspection space, with a long service life.